| Availability: | |

|---|---|

| Quantity: | |

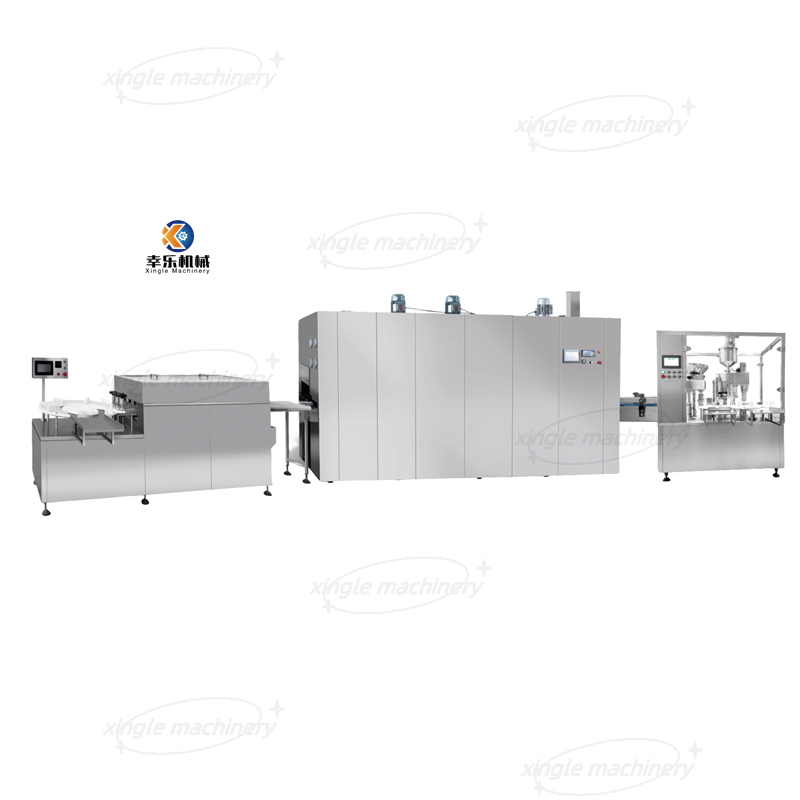

XL-DS-FLDX

XINGLE

Powder vial filling line perfectly integrates the entire process from bottle washing, drying, filling to sealing. It is suitable for vials of various specifications from 2ml to 100ml. It is an ideal solution for sterile powder production in the pharmaceutical, biotechnology and health care products industries.

Automatic Vial Powder Filling Production Line integrates advanced PLC and touch screen control systems, realizing a flexible mode of full-line linkage control and stand-alone independent operation. It not only ensures the continuity and high automation level of the production process, but also provides users with unparalleled operational convenience and specification adaptability.

This linkage line consists of four core equipment, forming a complete and continuous production system:

1. Auger type ultrasonic bottle washing machine:

Using ultrasonic deep cleaning technology, combined with purified water or water for injection, it can effectively remove particles, dust and residues inside and outside the bottle, providing clean packaging containers for subsequent processes.

2. High temperature tunnel oven:

The cleaned vials are continuously dried and sterilized. The hot air circulation is efficient and the sterilization temperature is uniform and stable, ensuring that the vials meet the sterile and pyrogen-free process requirements, providing guarantee for aseptic filling.

3. Powder filling machine:

Vial filling machine is specially designed for powder materials, with high filling accuracy and stable speed. Ensure that the filling volume of each bottle meets the preset standards and meets strict pharmaceutical production specifications.

4.Sealing machine:

Efficiently complete sealing operations such as rubber stoppers and aluminum caps (or plastic caps) with good sealing performance to ensure the sealing and safety of medicines during storage and transportation.

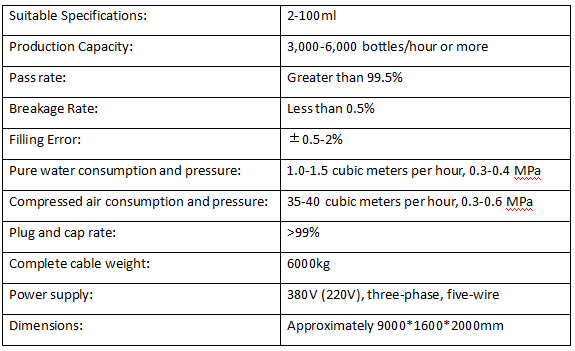

1. Excellent Flexibility: Vial filling and capping machine accommodates a wide range of vial sizes, from 2 to 100ml, allowing for convenient production changeovers and significantly improving equipment utilization.

2. High-Precision Filling: Utilizing advanced powder filling technology, this machine delivers precise filling volumes with a strict tolerance of ±0.5%-2% (according to pharmaceutical standards), ensuring consistent and stable product quality.

3. Outstanding Performance: Powder filling line operates stably, achieving a pass rate exceeding 99.5%, a bottle breakage rate below 0.5%, and a plugging/capping success rate exceeding 99%, effectively reducing material loss and production costs.

4. Intelligent Linkage Control: The control system, based on a PLC and touch screen, enables fully automated operation, centralized parameter setting, and real-time fault monitoring. It offers user-friendly human-machine interaction and simple operation.

5. Modular Design: The machine can be configured as a highly efficient linked production line for seamless production, or used as a standalone unit to meet diverse customer production needs.

The Powder Injection Vial Filling Line is widely used in various applications requiring aseptic filling of powders:

Lyophilized powder injections.

Antibiotic powder injections.

Biologic powders.

Nutrient powders.

Medical diagnostic reagents.

Powder vial filling line perfectly integrates the entire process from bottle washing, drying, filling to sealing. It is suitable for vials of various specifications from 2ml to 100ml. It is an ideal solution for sterile powder production in the pharmaceutical, biotechnology and health care products industries.

Automatic Vial Powder Filling Production Line integrates advanced PLC and touch screen control systems, realizing a flexible mode of full-line linkage control and stand-alone independent operation. It not only ensures the continuity and high automation level of the production process, but also provides users with unparalleled operational convenience and specification adaptability.

This linkage line consists of four core equipment, forming a complete and continuous production system:

1. Auger type ultrasonic bottle washing machine:

Using ultrasonic deep cleaning technology, combined with purified water or water for injection, it can effectively remove particles, dust and residues inside and outside the bottle, providing clean packaging containers for subsequent processes.

2. High temperature tunnel oven:

The cleaned vials are continuously dried and sterilized. The hot air circulation is efficient and the sterilization temperature is uniform and stable, ensuring that the vials meet the sterile and pyrogen-free process requirements, providing guarantee for aseptic filling.

3. Powder filling machine:

Vial filling machine is specially designed for powder materials, with high filling accuracy and stable speed. Ensure that the filling volume of each bottle meets the preset standards and meets strict pharmaceutical production specifications.

4.Sealing machine:

Efficiently complete sealing operations such as rubber stoppers and aluminum caps (or plastic caps) with good sealing performance to ensure the sealing and safety of medicines during storage and transportation.

1. Excellent Flexibility: Vial filling and capping machine accommodates a wide range of vial sizes, from 2 to 100ml, allowing for convenient production changeovers and significantly improving equipment utilization.

2. High-Precision Filling: Utilizing advanced powder filling technology, this machine delivers precise filling volumes with a strict tolerance of ±0.5%-2% (according to pharmaceutical standards), ensuring consistent and stable product quality.

3. Outstanding Performance: Powder filling line operates stably, achieving a pass rate exceeding 99.5%, a bottle breakage rate below 0.5%, and a plugging/capping success rate exceeding 99%, effectively reducing material loss and production costs.

4. Intelligent Linkage Control: The control system, based on a PLC and touch screen, enables fully automated operation, centralized parameter setting, and real-time fault monitoring. It offers user-friendly human-machine interaction and simple operation.

5. Modular Design: The machine can be configured as a highly efficient linked production line for seamless production, or used as a standalone unit to meet diverse customer production needs.

The Powder Injection Vial Filling Line is widely used in various applications requiring aseptic filling of powders:

Lyophilized powder injections.

Antibiotic powder injections.

Biologic powders.

Nutrient powders.

Medical diagnostic reagents.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong