| Availability: | |

|---|---|

| Quantity: | |

XL-DS-KLDX

XINGLE

Oral Liquid Filling Production Line adopts a "linked + single machine" dual-mode design, consisting of four core equipment: bottle washing machine, high-temperature tunnel oven, filling machine, and sealing machine. The linked line can realize full-process automation from bottle washing to product sealing; if the company has small-batch and personalized production needs, each equipment can also be split and used separately to flexibly respond to different production scenarios and take into account the dual needs of large-scale mass production and customized production.

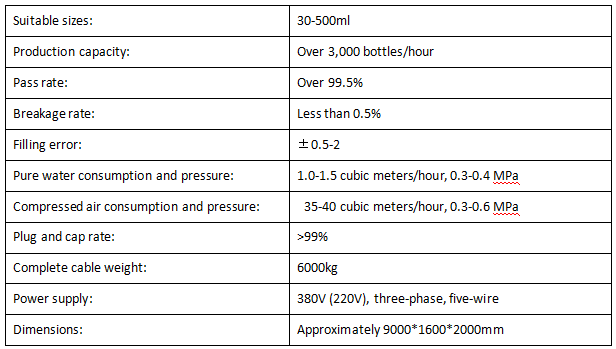

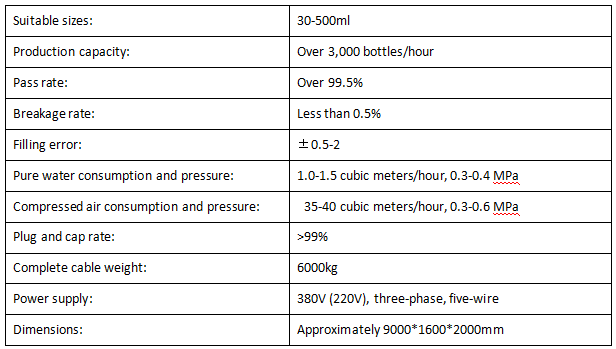

This production line demonstrates industry-leading performance, achieving high standards from capacity to quality:

1. High and Stable Output: The line can produce over 3,000 bottles per hour, meeting the mass production needs of medium- and large-scale enterprises and providing strong support for continuous product supply to the market.

2. High Quality and Efficiency: The Automated Vial Filling Production Line boasts a product qualification rate exceeding 99.5%, meaning the vast majority of products can be directly transferred to subsequent stages, significantly reducing rework and waste, and improving production efficiency.

3. Low Loss and Energy Saving: The bottle breakage rate is less than 0.5%, effectively reducing material loss costs and reducing the burden of waste disposal during the production process.

4. Precision Filling: The vial filling machine's filling tolerance strictly adheres to pharmaceutical standards, within a range of ±0.5-2, ensuring accurate dosage for each bottle and meeting industry quality standards.

5. Reliable Sealing: The plug and cap sealing rate exceeds 99%, ensuring product sealing, preventing liquid leakage and contamination, extending product shelf life, and maintaining stable product quality.

In the pharmaceutical industry, the production of oral liquid drugs (such as traditional Chinese medicine oral liquids, nutritional supplement oral liquids, therapeutic liquid medicines, etc.) has extremely high requirements for compliance, sterility, precision, and stability. Not only must they meet the strict standards of the National Medical Products Administration (NMPA) and GMP (Good Manufacturing Practice), but they must also avoid contamination risks and ensure accurate dosage throughout the entire production process to ensure the safety and effectiveness of the drugs.

Oral Liquid Filling Production Line adopts a "linked + single machine" dual-mode design, consisting of four core equipment: bottle washing machine, high-temperature tunnel oven, filling machine, and sealing machine. The linked line can realize full-process automation from bottle washing to product sealing; if the company has small-batch and personalized production needs, each equipment can also be split and used separately to flexibly respond to different production scenarios and take into account the dual needs of large-scale mass production and customized production.

This production line demonstrates industry-leading performance, achieving high standards from capacity to quality:

1. High and Stable Output: The line can produce over 3,000 bottles per hour, meeting the mass production needs of medium- and large-scale enterprises and providing strong support for continuous product supply to the market.

2. High Quality and Efficiency: The Automated Vial Filling Production Line boasts a product qualification rate exceeding 99.5%, meaning the vast majority of products can be directly transferred to subsequent stages, significantly reducing rework and waste, and improving production efficiency.

3. Low Loss and Energy Saving: The bottle breakage rate is less than 0.5%, effectively reducing material loss costs and reducing the burden of waste disposal during the production process.

4. Precision Filling: The vial filling machine's filling tolerance strictly adheres to pharmaceutical standards, within a range of ±0.5-2, ensuring accurate dosage for each bottle and meeting industry quality standards.

5. Reliable Sealing: The plug and cap sealing rate exceeds 99%, ensuring product sealing, preventing liquid leakage and contamination, extending product shelf life, and maintaining stable product quality.

In the pharmaceutical industry, the production of oral liquid drugs (such as traditional Chinese medicine oral liquids, nutritional supplement oral liquids, therapeutic liquid medicines, etc.) has extremely high requirements for compliance, sterility, precision, and stability. Not only must they meet the strict standards of the National Medical Products Administration (NMPA) and GMP (Good Manufacturing Practice), but they must also avoid contamination risks and ensure accurate dosage throughout the entire production process to ensure the safety and effectiveness of the drugs.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong