| Availability: | |

|---|---|

| Quantity: | |

XL-GS-YLDX

XINGLE

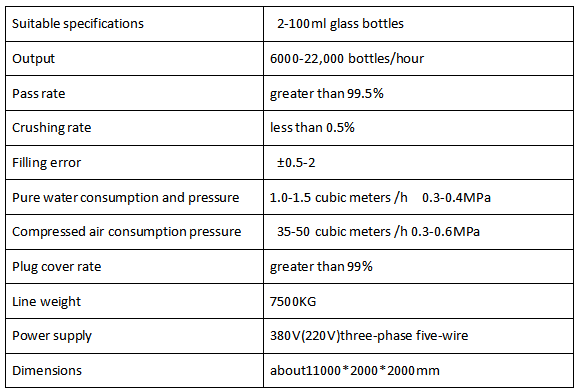

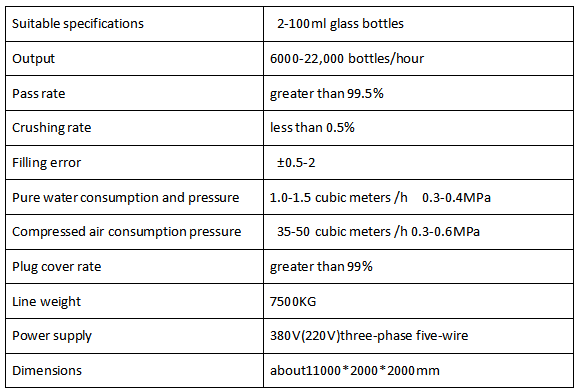

The Vial Filling Production Line is a fully automated, high-performance, integrated system that integrates vial washing, drying and sterilization, filling, stoppering, and capping. Designed specifically for vials ranging from 2 to 100 ml, it leverages cutting-edge technology to reshape production standards and provides a one-stop, seamless solution from empty to finished product, ensuring the sterility, precision, and safety of every product.

1. Superior Performance, Extraordinary Productivity

The Vial Filling Machine can produce 6,000 to 22,000 bottles per hour, meeting your current large-scale production needs while providing ample flexibility for future capacity expansion and easily adapting to market fluctuations.

2. Supreme Quality Control, Extremely Low Waste

1) Ultra-Low Breakage Rate: Utilizing flexible conveying technology and precise robotics, bottles are handled gently and smoothly, with a breakage rate strictly below 0.5% throughout the entire process, significantly reducing production costs and material waste.

2) Ultra-High Qualification Rate: Utilizing a sophisticated filling system and stable crimp-seal technology, aseptic filling and perfect sealing are ensured, resulting in a complete line qualification rate exceeding 99.5%.

3. Advanced Design, Stable and Reliable

1) Combining a modular design with a user-friendly interface, the machine boasts a well-organized layout, easy operation, maintenance, and cleaning, and complies with international standards such as cGMP/FDA.

2) The Oral Liquid Vial Filling Machine utilizes core components from renowned international brands. The meticulously designed and reinforced structure ensures continuous, stable operation, low failure rates, and long-lasting durability.

4. Widely adaptable, one machine for multiple uses

1) By replacing a few molds, it can quickly adapt to various glass vial sizes ranging from 2ml to 100ml, effectively improving equipment utilization and meeting the production needs of multiple varieties and batches.

2) The automatic vial filling machine is suitable for the final packaging of all liquid dosage forms, including injectable solutions, oral solutions, vaccines, biologics, high-end health products, cosmetic essences, and oral solutions.

Choose our integrated production line, choose a trusted partner:

1. High ROI: High efficiency and low losses directly translate into greater economic benefits.

2. Worry-free production: Excellent stability minimizes downtime, ensuring production schedules are met on time.

3. Quality assurance: Product sterility and seal integrity are ensured from the source, providing the solid foundation for passing stringent certifications.

4. Future-proof: Advanced design allows for future technology upgrades and IoT integration, helping you build a smart factory.

The Vial Filling Production Line is a fully automated, high-performance, integrated system that integrates vial washing, drying and sterilization, filling, stoppering, and capping. Designed specifically for vials ranging from 2 to 100 ml, it leverages cutting-edge technology to reshape production standards and provides a one-stop, seamless solution from empty to finished product, ensuring the sterility, precision, and safety of every product.

1. Superior Performance, Extraordinary Productivity

The Vial Filling Machine can produce 6,000 to 22,000 bottles per hour, meeting your current large-scale production needs while providing ample flexibility for future capacity expansion and easily adapting to market fluctuations.

2. Supreme Quality Control, Extremely Low Waste

1) Ultra-Low Breakage Rate: Utilizing flexible conveying technology and precise robotics, bottles are handled gently and smoothly, with a breakage rate strictly below 0.5% throughout the entire process, significantly reducing production costs and material waste.

2) Ultra-High Qualification Rate: Utilizing a sophisticated filling system and stable crimp-seal technology, aseptic filling and perfect sealing are ensured, resulting in a complete line qualification rate exceeding 99.5%.

3. Advanced Design, Stable and Reliable

1) Combining a modular design with a user-friendly interface, the machine boasts a well-organized layout, easy operation, maintenance, and cleaning, and complies with international standards such as cGMP/FDA.

2) The Oral Liquid Vial Filling Machine utilizes core components from renowned international brands. The meticulously designed and reinforced structure ensures continuous, stable operation, low failure rates, and long-lasting durability.

4. Widely adaptable, one machine for multiple uses

1) By replacing a few molds, it can quickly adapt to various glass vial sizes ranging from 2ml to 100ml, effectively improving equipment utilization and meeting the production needs of multiple varieties and batches.

2) The automatic vial filling machine is suitable for the final packaging of all liquid dosage forms, including injectable solutions, oral solutions, vaccines, biologics, high-end health products, cosmetic essences, and oral solutions.

Choose our integrated production line, choose a trusted partner:

1. High ROI: High efficiency and low losses directly translate into greater economic benefits.

2. Worry-free production: Excellent stability minimizes downtime, ensuring production schedules are met on time.

3. Quality assurance: Product sterility and seal integrity are ensured from the source, providing the solid foundation for passing stringent certifications.

4. Future-proof: Advanced design allows for future technology upgrades and IoT integration, helping you build a smart factory.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong