| Availability: | |

|---|---|

| Quantity: | |

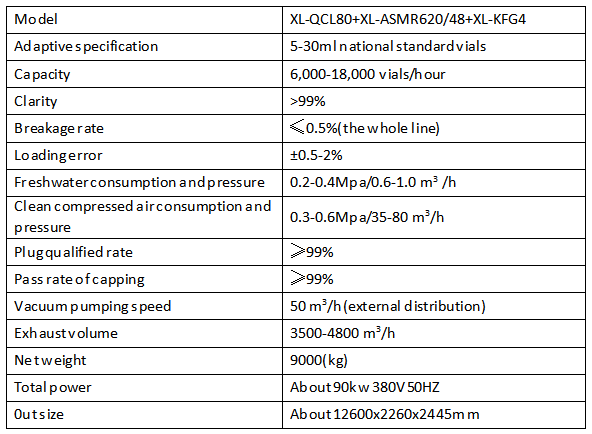

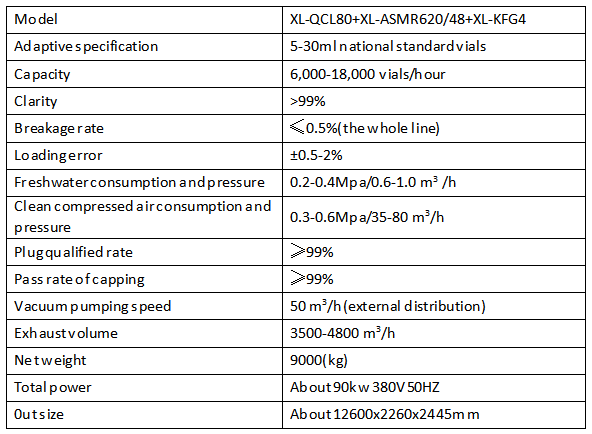

XL-QCL80+XL-ASMR620/48+XL-KFG4

XINGLE

The vial powder filling machine line consists of a vertical ultrasonic bottle washer, a tunnel-type hot air sterilization oven, and a vertical filling and sealing machine. The entire line integrates water spraying, ultrasonic cleaning, water and air flushing, drying and sterilization, cooling, filling, and sealing processes, encompassing a fully automated process from bottle cleaning to finished product delivery.

The vial filling line utilizes advanced design concepts and a stable and reliable structure to ensure pharmaceutical production complies with GMP standards and provides strong equipment and technical support for sterile preparations.

1. Space Optimization and Easy Cleaning: The equipment features a simple and compact design with a smooth surface and no blind spots, allowing for thorough cleaning and maintenance, meeting the high standards of a sterile production environment.

2. High Performance and Stability: The integrated line operates smoothly, with a bottle breakage rate of ≤0.5%, clarity >99%, and a filling accuracy of ±0.5-2% (in compliance with pharmacopoeia standards), ensuring consistent product quality.

3. Energy-Saving and Environmentally Friendly Design: Optimized resource consumption, with fresh water consumption of 0.6-1.0 m³/h and compressed air consumption of 35-80 m³/h. Combined with a highly efficient hot air circulation and exhaust system (3,500-4,800 m³/h), this system reduces energy consumption and operating costs.

4. Intelligent Interconnected Control: Each unit seamlessly connects to achieve fully automated operation, achieving a maximum production capacity of 18,000 bottles per hour, significantly improving production efficiency while reducing manual intervention.

Applications

Vial Powder Filling Production Line is specifically designed for aseptic filling and sealing of small-volume injectables (powder injections) in the pharmaceutical industry. It is suitable for the production of high-risk products such as biologics, chemical drugs, and vaccines, making it an ideal choice for improving drug safety and production efficiency.

Compliance

Automatic vial filling machine is designed and manufactured in full compliance with China's Good Manufacturing Practice (GMP) and meets international GMP standards, ensuring compliance and reliability throughout the entire process, from cleaning and sterilization to filling and sealing.

The vial powder filling machine line consists of a vertical ultrasonic bottle washer, a tunnel-type hot air sterilization oven, and a vertical filling and sealing machine. The entire line integrates water spraying, ultrasonic cleaning, water and air flushing, drying and sterilization, cooling, filling, and sealing processes, encompassing a fully automated process from bottle cleaning to finished product delivery.

The vial filling line utilizes advanced design concepts and a stable and reliable structure to ensure pharmaceutical production complies with GMP standards and provides strong equipment and technical support for sterile preparations.

1. Space Optimization and Easy Cleaning: The equipment features a simple and compact design with a smooth surface and no blind spots, allowing for thorough cleaning and maintenance, meeting the high standards of a sterile production environment.

2. High Performance and Stability: The integrated line operates smoothly, with a bottle breakage rate of ≤0.5%, clarity >99%, and a filling accuracy of ±0.5-2% (in compliance with pharmacopoeia standards), ensuring consistent product quality.

3. Energy-Saving and Environmentally Friendly Design: Optimized resource consumption, with fresh water consumption of 0.6-1.0 m³/h and compressed air consumption of 35-80 m³/h. Combined with a highly efficient hot air circulation and exhaust system (3,500-4,800 m³/h), this system reduces energy consumption and operating costs.

4. Intelligent Interconnected Control: Each unit seamlessly connects to achieve fully automated operation, achieving a maximum production capacity of 18,000 bottles per hour, significantly improving production efficiency while reducing manual intervention.

Applications

Vial Powder Filling Production Line is specifically designed for aseptic filling and sealing of small-volume injectables (powder injections) in the pharmaceutical industry. It is suitable for the production of high-risk products such as biologics, chemical drugs, and vaccines, making it an ideal choice for improving drug safety and production efficiency.

Compliance

Automatic vial filling machine is designed and manufactured in full compliance with China's Good Manufacturing Practice (GMP) and meets international GMP standards, ensuring compliance and reliability throughout the entire process, from cleaning and sterilization to filling and sealing.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong