| Availability: | |

|---|---|

| Quantity: | |

XL-DS-KFY

XINGLE

As an integrated washing, drying and filling unit of the oral liquid production line, Vial Filling Line is specially designed for 10ml (20ml) easy-open cap (aluminum plastic cap) straight bottles. It integrates multiple functions such as cleaning, drying, filling, capping, sealing, etc., to achieve seamless connection throughout the production process, effectively reducing intermediate transfer links, reducing the risk of product contamination, and providing strong support for enterprises to improve production efficiency.

1. Scientific bottle feeding and cleaning to lay the foundation for cleanliness

The screw feeds bottles in a stable and orderly manner, preventing collisions and jamming; pressure water flushing eliminates impurities and stains in all directions and meets medical and health standards.

2. Efficient drying to ensure bottle dryness

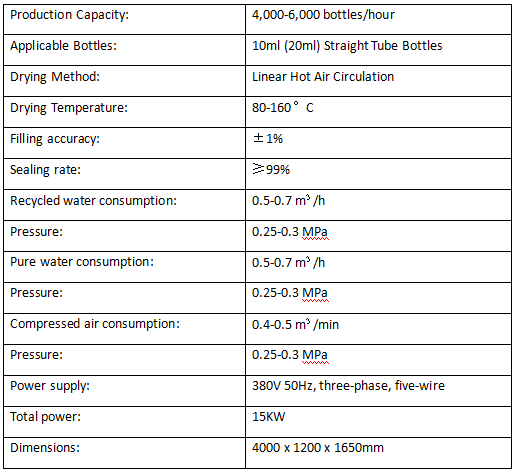

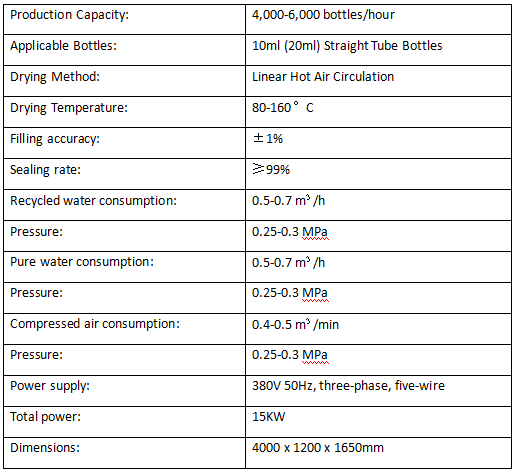

Linear hot air circulation drying, the hot air is uniform, efficient and stable, and can quickly remove residual moisture; the temperature is adjustable from 80 to 160°C, adapting to the needs and bottle materials, ensuring compliance with standards and preventing damage.

3. Precise filling and stable sealing to control product quality

(1) Four-head filling: The vial filling sealing machine is equipped with a four-head filling system. The filling speed is fast, and the filling accuracy can be controlled within ±1%, which effectively ensures the consistency of the filling volume, reduces product loss, and improves product quality stability.

(2) Electromagnetic oscillation cap feeding: Using advanced electromagnetic oscillation cap feeding technology, the cap feeding is stable and efficient. It can accurately transport the cap to the designated position, avoid cap jamming, misalignment and other problems, and provide reliable guarantee for the subsequent sealing process.

(3) Three-knife centrifugal capping: The sealing link adopts a three-knife centrifugal capping design. The sealing is tight and firm, and the sealing rate is as high as ≥99%. It effectively prevents leakage, contamination, etc. of oral liquids during storage and transportation, and ensures product quality and safety.

1. Automatic Oral Liquid Filling Line is widely used in pharmaceutical factories, health care product manufacturers, etc., and can be used for the large-scale production of various oral liquid products.

2. Whether it is small batch trial production or medium and large-scale mass production, its stable performance, precise control and efficient production capacity can help companies reduce production costs, improve production efficiency and product quality, and enhance the company's core competitiveness in the market.

3. We can provide customized solutions for different companies - whether it is adjusting the size of equipment in the company's existing factory layout, or optimizing process parameters for special product characteristics, we will create tailor-made adaptation solutions.

As an integrated washing, drying and filling unit of the oral liquid production line, Vial Filling Line is specially designed for 10ml (20ml) easy-open cap (aluminum plastic cap) straight bottles. It integrates multiple functions such as cleaning, drying, filling, capping, sealing, etc., to achieve seamless connection throughout the production process, effectively reducing intermediate transfer links, reducing the risk of product contamination, and providing strong support for enterprises to improve production efficiency.

1. Scientific bottle feeding and cleaning to lay the foundation for cleanliness

The screw feeds bottles in a stable and orderly manner, preventing collisions and jamming; pressure water flushing eliminates impurities and stains in all directions and meets medical and health standards.

2. Efficient drying to ensure bottle dryness

Linear hot air circulation drying, the hot air is uniform, efficient and stable, and can quickly remove residual moisture; the temperature is adjustable from 80 to 160°C, adapting to the needs and bottle materials, ensuring compliance with standards and preventing damage.

3. Precise filling and stable sealing to control product quality

(1) Four-head filling: The vial filling sealing machine is equipped with a four-head filling system. The filling speed is fast, and the filling accuracy can be controlled within ±1%, which effectively ensures the consistency of the filling volume, reduces product loss, and improves product quality stability.

(2) Electromagnetic oscillation cap feeding: Using advanced electromagnetic oscillation cap feeding technology, the cap feeding is stable and efficient. It can accurately transport the cap to the designated position, avoid cap jamming, misalignment and other problems, and provide reliable guarantee for the subsequent sealing process.

(3) Three-knife centrifugal capping: The sealing link adopts a three-knife centrifugal capping design. The sealing is tight and firm, and the sealing rate is as high as ≥99%. It effectively prevents leakage, contamination, etc. of oral liquids during storage and transportation, and ensures product quality and safety.

1. Automatic Oral Liquid Filling Line is widely used in pharmaceutical factories, health care product manufacturers, etc., and can be used for the large-scale production of various oral liquid products.

2. Whether it is small batch trial production or medium and large-scale mass production, its stable performance, precise control and efficient production capacity can help companies reduce production costs, improve production efficiency and product quality, and enhance the company's core competitiveness in the market.

3. We can provide customized solutions for different companies - whether it is adjusting the size of equipment in the company's existing factory layout, or optimizing process parameters for special product characteristics, we will create tailor-made adaptation solutions.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong