| Availability: | |

|---|---|

| Quantity: | |

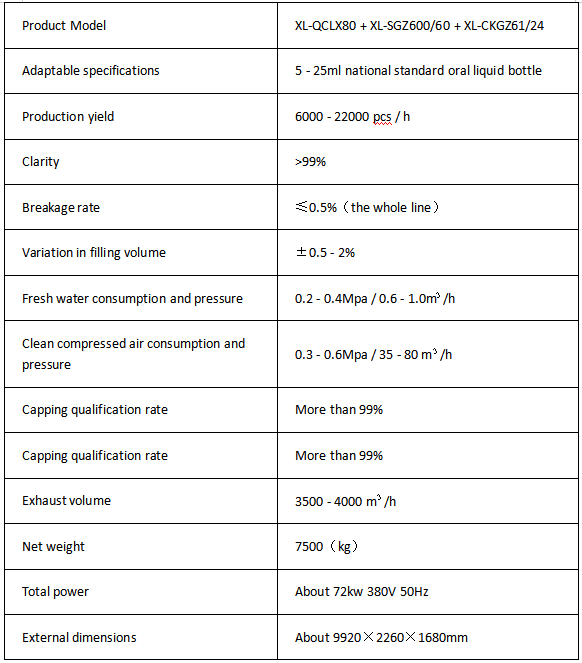

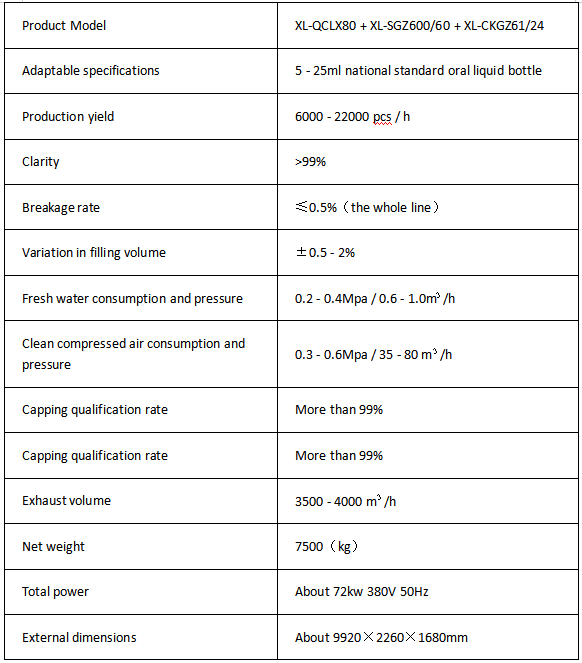

XL-QCLX80 + XL-SGZ600/60 + XL-CKGZ61/24

XINGLE

Oral Liquid Filling Production Line is a high-precision, high-efficiency, and highly stable intelligent solution tailored for modern pharmaceutical companies, leveraging years of technological expertise and industry insights. This production line integrates core modules, including a vertical ultrasonic bottle washer, a tunnel-type sterilization oven, and a filler and capper, achieving fully automated production from oral liquid bottle processing to finished product delivery.

Liquid vial filling line seamlessly completes the following fully automated process steps:

Bottle infeed → Water spraying → Ultrasonic rough and fine washing → Water rinsing → Air flushing (blow-drying) → Drying and sterilization → Cooling → Filling → Capping → Capping → Bottle delivery

1. Superior Performance, High Capacity

The production line operates stably and efficiently, with a wide production capacity range (6,000-22,000 bottles/hour). It can flexibly meet your needs, from pilot production to large-scale commercial production, significantly improving your return on investment.

2. Top-notch Quality, Worry-Free

1) High Clarity: A unique combination of ultrasonic cleaning and multi-station water-air rinsing ensures bottle cleanliness, achieving product clarity >99%.

2) Low Breakage Rate: The automatic vial filling machine operates smoothly, utilizing flexible conveying and precise positioning technology throughout the line to strictly control bottle breakage to below 0.5%, significantly reducing material loss.

3) Precision Filling: The vial filling machine utilizes a high-precision filling system, with a filling volume deviation strictly adhering to the Chinese Pharmacopoeia standard (±0.5% - 2%), ensuring the correct dosage for each vial.

3. Stable, Reliable, and Efficient Interconnection

1) Ultra-High Qualification Rate: The sophisticated capping and capping systems ensure a capping and capping qualification rate exceeding 99%, effectively guaranteeing product sealing and integrity.

2) Seamless Integration: Smooth integration between individual modules eliminates contamination and efficiency loss caused by intermediate turnover, ensuring high continuous operation and a very low failure rate.

4. Regulatory Compliance and Safety

The entire line is designed in strict compliance with GMP requirements, and its structure is easy to clean and maintain. The tunnel oven provides efficient drying, sterilization, and cooling functions, ensuring product sterility and safeguarding the safety of your pharmaceuticals.

Why choose our production line?

1. One-stop solution: We offer a complete process from cleaning and sterilization to filling and capping, reducing equipment integration hassles and lowering procurement and maintenance costs.

2. Intelligent control: Equipped with a PLC control system and human-machine interface (HMI), our production line is easy to operate, offers flexible parameter settings, and provides traceable production data.

3. Durability: Our sophisticated manufacturing process and high-quality materials ensure a long service life and continuous stability.

4. Professional support: We offer a full range of professional services, from installation and commissioning to operator training and after-sales maintenance, making us your reliable production partner.

Oral Liquid Filling Production Line is a high-precision, high-efficiency, and highly stable intelligent solution tailored for modern pharmaceutical companies, leveraging years of technological expertise and industry insights. This production line integrates core modules, including a vertical ultrasonic bottle washer, a tunnel-type sterilization oven, and a filler and capper, achieving fully automated production from oral liquid bottle processing to finished product delivery.

Liquid vial filling line seamlessly completes the following fully automated process steps:

Bottle infeed → Water spraying → Ultrasonic rough and fine washing → Water rinsing → Air flushing (blow-drying) → Drying and sterilization → Cooling → Filling → Capping → Capping → Bottle delivery

1. Superior Performance, High Capacity

The production line operates stably and efficiently, with a wide production capacity range (6,000-22,000 bottles/hour). It can flexibly meet your needs, from pilot production to large-scale commercial production, significantly improving your return on investment.

2. Top-notch Quality, Worry-Free

1) High Clarity: A unique combination of ultrasonic cleaning and multi-station water-air rinsing ensures bottle cleanliness, achieving product clarity >99%.

2) Low Breakage Rate: The automatic vial filling machine operates smoothly, utilizing flexible conveying and precise positioning technology throughout the line to strictly control bottle breakage to below 0.5%, significantly reducing material loss.

3) Precision Filling: The vial filling machine utilizes a high-precision filling system, with a filling volume deviation strictly adhering to the Chinese Pharmacopoeia standard (±0.5% - 2%), ensuring the correct dosage for each vial.

3. Stable, Reliable, and Efficient Interconnection

1) Ultra-High Qualification Rate: The sophisticated capping and capping systems ensure a capping and capping qualification rate exceeding 99%, effectively guaranteeing product sealing and integrity.

2) Seamless Integration: Smooth integration between individual modules eliminates contamination and efficiency loss caused by intermediate turnover, ensuring high continuous operation and a very low failure rate.

4. Regulatory Compliance and Safety

The entire line is designed in strict compliance with GMP requirements, and its structure is easy to clean and maintain. The tunnel oven provides efficient drying, sterilization, and cooling functions, ensuring product sterility and safeguarding the safety of your pharmaceuticals.

Why choose our production line?

1. One-stop solution: We offer a complete process from cleaning and sterilization to filling and capping, reducing equipment integration hassles and lowering procurement and maintenance costs.

2. Intelligent control: Equipped with a PLC control system and human-machine interface (HMI), our production line is easy to operate, offers flexible parameter settings, and provides traceable production data.

3. Durability: Our sophisticated manufacturing process and high-quality materials ensure a long service life and continuous stability.

4. Professional support: We offer a full range of professional services, from installation and commissioning to operator training and after-sales maintenance, making us your reliable production partner.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong