| Availability: | |

|---|---|

| Quantity: | |

XL-GKP

XINGLE

This wide-mouth bottle liquid-filling line is a high-performance automated system that integrates cleaning, filling, sealing, and labeling. With its exceptional flexibility, stability, and intelligent control, the line can easily handle the packaging needs of a wide range of round, square, flat, and even special-shaped bottles, from 50ml to 1000ml. It is an ideal choice for large-scale, standardized production in industries such as food, beverages, pharmaceuticals, and condiments.

1. Excellent Compatibility and Flexibility

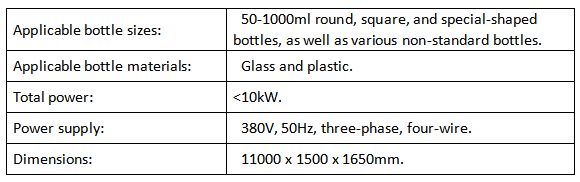

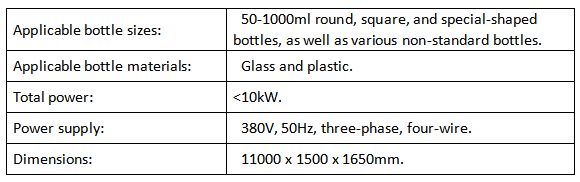

1) The Linkage Filling Line is widely applicable to round, square, and shaped bottles (50-1000ml), as well as various non-standard and custom bottle shapes.

2) Whether demanding the high quality of glass bottles or the lightweight design of plastic bottles, this line perfectly adapts to meet the packaging needs of diverse market segments.

2. Highly Automated and Stable and Efficient

1) Seamless integration of the bottle washer, unscrambler, filler, sealer, and labeler (with either glue or self-adhesive labeling) enables fully automated flow from empty bottles to finished products, reducing labor costs and intervention risks.

2) The Jam Filling Line can operate in a linked fashion for maximum efficiency, or each unit can operate independently, adapting to small-batch, high-variety production models and flexibly responding to market changes.

3. Advanced Cleaning and Filling Technology

1) Ultrasonic cleaning technology effectively removes stubborn stains and microorganisms from both the inside and outside of bottles, ensuring high standards of container cleanliness.

2) The filling system is optimized for materials of varying viscosities (from fluid beverages to thick jams and syrups), ensuring high filling accuracy.

4. Intelligent Control and Stability and Reliability

1) Both PLC program control and standard control modes are available. The PLC control system is highly intelligent, offering simple parameter settings, stable operation, low failure rates, and convenient data monitoring and traceability.

2) The Liquid Filling Line features a compact design, a rational layout, low noise levels, and economical energy consumption (total power <10 kW), meeting the energy-saving and environmental protection requirements of modern factories.

This production line is a valuable tool for the following industries:

1. Alcoholic beverages: packaging of health wines, medicinal wines, white wines, yellow wines, and fruit wines in wide-mouth bottles.

2. Beverages: packaging of juices, syrups, yogurts, and fruit drinks.

3. Foods: packaging of jams, honey, salad dressings, condiments, and cooking oils.

4. Pharmaceuticals: packaging of syrups, oral solutions, and topical medications.

5. Daily chemical products: packaging of certain high-viscosity daily chemical products.

This wide-mouth bottle liquid-filling line is a high-performance automated system that integrates cleaning, filling, sealing, and labeling. With its exceptional flexibility, stability, and intelligent control, the line can easily handle the packaging needs of a wide range of round, square, flat, and even special-shaped bottles, from 50ml to 1000ml. It is an ideal choice for large-scale, standardized production in industries such as food, beverages, pharmaceuticals, and condiments.

1. Excellent Compatibility and Flexibility

1) The Linkage Filling Line is widely applicable to round, square, and shaped bottles (50-1000ml), as well as various non-standard and custom bottle shapes.

2) Whether demanding the high quality of glass bottles or the lightweight design of plastic bottles, this line perfectly adapts to meet the packaging needs of diverse market segments.

2. Highly Automated and Stable and Efficient

1) Seamless integration of the bottle washer, unscrambler, filler, sealer, and labeler (with either glue or self-adhesive labeling) enables fully automated flow from empty bottles to finished products, reducing labor costs and intervention risks.

2) The Jam Filling Line can operate in a linked fashion for maximum efficiency, or each unit can operate independently, adapting to small-batch, high-variety production models and flexibly responding to market changes.

3. Advanced Cleaning and Filling Technology

1) Ultrasonic cleaning technology effectively removes stubborn stains and microorganisms from both the inside and outside of bottles, ensuring high standards of container cleanliness.

2) The filling system is optimized for materials of varying viscosities (from fluid beverages to thick jams and syrups), ensuring high filling accuracy.

4. Intelligent Control and Stability and Reliability

1) Both PLC program control and standard control modes are available. The PLC control system is highly intelligent, offering simple parameter settings, stable operation, low failure rates, and convenient data monitoring and traceability.

2) The Liquid Filling Line features a compact design, a rational layout, low noise levels, and economical energy consumption (total power <10 kW), meeting the energy-saving and environmental protection requirements of modern factories.

This production line is a valuable tool for the following industries:

1. Alcoholic beverages: packaging of health wines, medicinal wines, white wines, yellow wines, and fruit wines in wide-mouth bottles.

2. Beverages: packaging of juices, syrups, yogurts, and fruit drinks.

3. Foods: packaging of jams, honey, salad dressings, condiments, and cooking oils.

4. Pharmaceuticals: packaging of syrups, oral solutions, and topical medications.

5. Daily chemical products: packaging of certain high-viscosity daily chemical products.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong