Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

The pharmaceutical industry depends heavily on cutting-edge equipment to ensure drug safety and quality. Choosing the right equipment suppliers is crucial for meeting strict safety and regulatory standards. With technological advancements and increased global health demands, selecting the best manufacturer is more important than ever. In this post, we'll explore the top 10 pharmaceutical equipment manufacturers of 2025 and highlight their key strengths.

The pharmaceutical manufacturing industry heavily relies on specialized equipment to ensure the production of high-quality medications. In this section, we'll explore the top 10 pharmaceutical equipment manufacturers, each with its unique strengths, key products, and contributions to the industry. From automation to sustainability, these companies lead the way in developing and supplying cutting-edge equipment for pharmaceutical manufacturing.

GEA Group, based in Germany, has a long-standing history since its establishment in 1881. Known for its wide-ranging involvement across multiple industries, GEA stands out in pharmaceutical machinery, providing solutions globally.

GEA's product lineup includes:

● Liquid processing

● Powder handling

● Aseptic processing equipment

GEA has earned recognition for its commitment to sustainability and digitalization, continually enhancing its equipment to meet environmental standards while incorporating the latest technological advancements. GEA's emphasis on advanced process technologies helps ensure that pharmaceutical products are manufactured with high efficiency and reliability. Additionally, GEA's integrated solutions allow for automation and reduced human error, offering a higher degree of production consistency. Their focus on sustainable practices ensures that they reduce energy consumption and minimize waste, making them a top choice for environmentally-conscious manufacturers.

Founded in 1961 in Italy, IMA Group has expanded its presence to more than 80 countries. Known for its innovative approach, IMA has become a trusted name in the pharmaceutical, cosmetics, and food industries.

IMA offers a wide range of pharmaceutical equipment, such as:

● Tablet presses

● Capsule fillers

● Packaging solutions

IMA is renowned for its extensive R&D and boasts over 1,700 patents. This dedication to continuous innovation helps the company stay at the forefront of the pharmaceutical machinery industry. IMA's cutting-edge technologies are designed to improve production efficiency, reduce downtime, and enhance product quality. The company is also known for its customized solutions, ensuring that each piece of equipment can be tailored to meet the specific needs of pharmaceutical manufacturers. Additionally, IMA's global presence allows them to offer localized support, making them a highly reliable partner for companies worldwide.

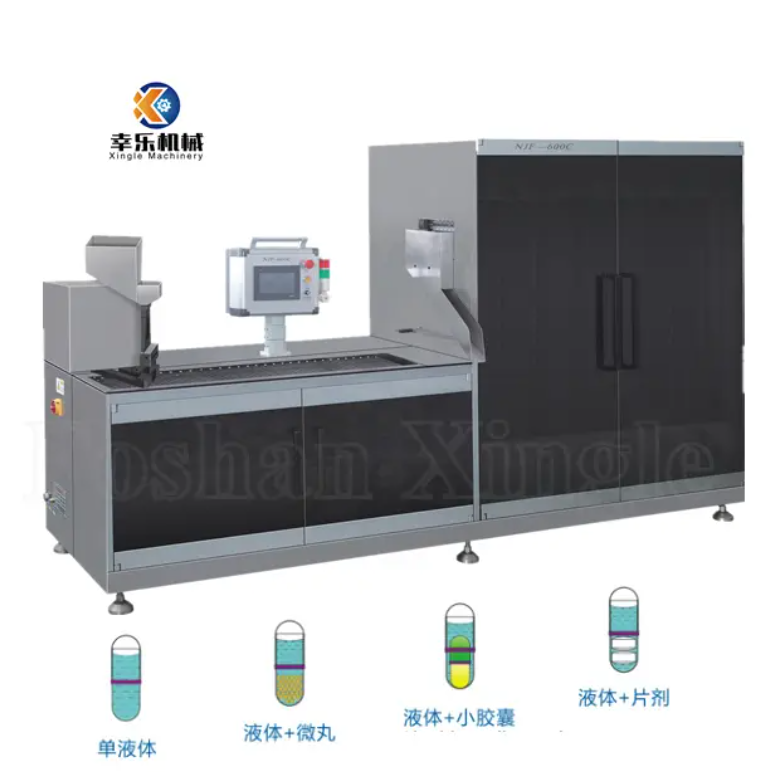

Established in 2020 and based in Foshan, China, Xingle Machinery Equipment specializes in providing high-quality pharmaceutical machinery to various industries. Despite being relatively new, the company's growth has been rapid, driven by its innovative solutions and commitment to quality.

Xingle Machinery offers:

● Capsule Filling Machines

● Counting and Capping Lines

● Liquid and Powder Filling Lines

Xingle stands out with its automatic and semi-automatic solutions, catering to a wide range of client needs. It also offers customized production lines, ensuring clients receive tailored machinery. The company is fully compliant with international standards, such as GMP and cGMP, and offers strong after-sales support, including a 1-year warranty. Xingle's innovative approach allows them to deliver cost-effective solutions without compromising on quality. Additionally, their user-friendly designs and efficient machinery contribute to high throughput and operational efficiency, making them a favorite for small and medium-sized enterprises (SMEs) looking for reliable, affordable solutions.

Formerly known as Bosch Packaging Technology, Syntegon continues to operate as a prominent player in pharmaceutical equipment manufacturing. Based in Germany, Syntegon is dedicated to high-quality production and innovation in packaging technologies.

Syntegon's product range includes:

● Capsule fillers

● Tablet presses

● Packaging machines

Syntegon focuses on technological innovation, delivering high-efficiency, high-quality equipment that optimizes production processes. Their intelligent automation solutions enable pharmaceutical companies to streamline manufacturing while reducing costs. Syntegon's machines are designed with ease of integration in mind, allowing them to seamlessly fit into existing production lines. Their strong emphasis on digitization and data analytics also helps manufacturers track and optimize production, leading to greater overall efficiency. Syntegon's commitment to sustainability is also evident in their development of energy-efficient machinery, which helps minimize environmental impact.

ACG Worldwide, founded in 1961, is an Indian multinational company offering a global presence. With operations in over 130 countries, it is a major player in pharmaceutical equipment manufacturing.

ACG provides a variety of solutions such as:

● Capsule filling machines

● Tablet presses

● Packaging solutions

ACG is known for its integrated solutions, covering everything from formulation to packaging. This comprehensive approach helps customers streamline production while maintaining product quality and compliance. ACG's advanced technology is focused on improving product consistency and reducing operational costs. They are also highly regarded for their commitment to sustainability, developing machines that reduce material waste and improve energy efficiency. Furthermore, ACG's customer-centric approach allows them to customize their equipment to meet specific industry needs, providing a high level of flexibility in production lines.

Romaco, a German-based company founded in 1989, is recognized for providing solutions across multiple industries, including pharmaceuticals, food, and cosmetics.

Romaco's equipment offerings include:

● Granulation

● Tableting

● Coating

● Blister packaging

Romaco is known for integrated production lines and a robust remote support service, ensuring seamless operations and quick troubleshooting for clients. The company's solutions emphasize efficiency, quality control, and product integrity. Romaco's modular approach enables customers to tailor systems to their needs, ensuring that each production line meets specific manufacturing goals. Additionally, their flexible equipment design allows for easy upgrades and scalability, making them an ideal choice for businesses looking to future-proof their production facilities.

Based in Germany, Glatt Group has become a pioneer in fluidized bed technology. The company specializes in providing high-performance machinery for the pharmaceutical sector.

Glatt offers:

● Fluid bed processors

● Dry granulation machines

● Coaters

Glatt continues to lead in continuous innovation in pharmaceutical processing technology, ensuring optimal product consistency and high efficiency in production lines. Their advanced granulation systems are widely used for high-speed tablet production, ensuring uniformity and enhanced bioavailability of the final products. Glatt's focus on quality and precision has earned them a reputation for reliability, making them a preferred choice for manufacturers seeking top-tier process equipment.

With over 350 years of history, Merck KGaA, headquartered in Darmstadt, Germany, is one of the oldest and most respected companies in the industry. Merck offers a broad range of products and services in life sciences and healthcare.

Merck's product offerings include:

● Chromatography resins

● Single-use systems

● Filters

Merck is distinguished by its scientific and technological breakthroughs, providing cutting-edge solutions in pharmaceutical production and biopharmaceuticals. Their highly specialized products are critical for improving the purity and efficacy of pharmaceutical compounds. Merck is also known for its strong partnerships with industry leaders, enabling them to stay ahead of emerging trends and challenges in drug production.

Bausch+Ströbel, a key player in the pharmaceutical sector, specializes in packaging and filling systems. The company has earned global recognition for its precision equipment.

Key products include:

● Filling and sealing machines

● Ampoule processing systems

Bausch+Ströbel is celebrated for its precision equipment and regulatory compliance, ensuring that products meet the highest standards for quality and safety. Their highly automated systems improve efficiency while minimizing human error. Bausch+Ströbel is also known for its customized solutions, providing equipment that suits the unique needs of pharmaceutical manufacturers, especially those in the sterile production space.

Based in the United States, Paul Mueller specializes in providing stainless steel process equipment, particularly for industries requiring hygienic designs and robust solutions.

Paul Mueller's range includes:

● Integrated process systems

● Mixers

● Dryers

● Storage containers

Paul Mueller's expertise lies in its hygiene and durable design, which makes its equipment ideal for pharmaceutical and food industries, where cleanliness and durability are critical. The company's custom-built solutions ensure optimal performance, meeting the stringent requirements of pharmaceutical manufacturing. Their focus on quality control and long-term maintenance solutions further enhances the value they bring to the market.

In this section, we've highlighted some of the leading players in pharmaceutical equipment manufacturing. From GEA's commitment to sustainability to Xingle's customized solutions, these companies have shaped the industry with their innovation, expertise, and global reach.

Pharmaceutical equipment is essential for producing high-quality drugs. Each type of equipment plays a specific role in different stages of the production process. Here's a breakdown:

● Capsule Filling Machines: These machines fill hard gelatin or soft capsules with precise doses of active ingredients, often in powder, granule, or pellet form. They ensure uniformity in dosage, minimize contamination risks, and ensure the integrity of the drug inside the capsule.

● Tablet Pressing Machines: Tablet presses are used to compress raw materials (like powders) into tablets of uniform size, shape, and weight. They help maintain consistent dosage and can be adjusted to produce different tablet sizes and strengths, ensuring both safety and effectiveness in pharmaceutical production.

● Powder Handling Equipment: Powder handling equipment ensures the safe transfer, mixing, and storage of raw powders used in drug production. Proper handling is crucial, as powder particles can be hazardous, and improper mixing can lead to inconsistent drug formulations.

● Liquid Production and Filling Machines: These machines are essential for the production of liquid pharmaceuticals such as syrups, vaccines, and injectable drugs. They accurately measure and fill liquid formulations into vials, bottles, or syringes, minimizing spills and maintaining sterility. Ensuring consistency in liquid formulations is key to meeting regulatory standards.

● Coating Machines: Coating is an important step, especially for oral tablets and capsules. These machines apply a protective layer over the drug, which can help control the drug's release, mask unpleasant tastes, and protect active ingredients from environmental factors like moisture and light.

● Packaging Equipment: After production, packaging equipment ensures that medications are properly sealed, labeled, and protected. This includes blister packaging, bottling, and labeling machines. Proper packaging ensures the drug remains safe and effective throughout storage and transport.

The pharmaceutical industry operates under strict regulations, and the equipment used must adhere to high standards. Here's how pharmaceutical equipment helps ensure drug quality and regulatory compliance:

● GMP (Good Manufacturing Practice) Standards: Pharmaceutical equipment must comply with GMP, a set of guidelines that ensure consistent manufacturing quality. These standards are critical in preventing contamination, mix-ups, and ensuring that drugs meet the required safety and quality criteria. Equipment designed to meet GMP standards must be capable of maintaining sterile conditions and precise control over production processes.

● Importance of Automation, Precision, and Safety: Modern pharmaceutical equipment is highly automated, reducing human error and improving precision. Automated systems ensure that each batch of medication is produced with exact specifications, leading to uniformity in drug dosage and effectiveness. Automation also enhances the safety of drug production by reducing the risk of exposure to hazardous materials and providing more control over the process.

● Regulatory Compliance (FDA, WHO-GMP): Compliance with global regulatory standards, such as those set by the FDA and WHO-GMP, is essential for pharmaceutical equipment. These regulations ensure that the equipment meets the highest standards for drug quality, efficacy, and safety. Companies that manufacture pharmaceutical equipment must continuously update their machines to adhere to these evolving standards, ensuring that medications produced are safe for patient use and effective in their intended treatments.

Choosing the right pharmaceutical equipment is crucial for ensuring efficiency, quality, and compliance in drug production. Here's a guide to help you make the right choice.

Before selecting equipment, consider your production needs. Ask yourself:

● Batch vs. Continuous Production: Are you producing in small batches or large quantities? Batch production requires flexibility, while continuous production demands high efficiency and automation.

● Scale of Operation: What is the size of your operation? Smaller facilities may need more compact, cost-effective machinery, while larger operations might require industrial-scale equipment.

● Product Type: Are you producing solid dosage forms, liquids, or injectables? Different types of products need different machinery, such as capsule fillers for solids or filling machines for liquids.

Pharmaceutical manufacturing must meet stringent regulatory standards. When choosing equipment, ensure it complies with these regulations:

● GMP Compliance: Equipment must adhere to Good Manufacturing Practice (GMP) guidelines to ensure safe and effective production.

● FDA and WHO-GMP Standards: Depending on your market, your equipment must also meet the standards of regulatory bodies like the FDA (in the U.S.) and WHO-GMP (globally). These agencies ensure the equipment produces drugs under controlled conditions, minimizing risks.

Failure to comply can lead to costly fines and disruptions in production, so regulatory compliance is a must.

Investing in pharmaceutical equipment is a long-term commitment. Here's how to ensure your investment stays relevant:

● Scalability: Choose equipment that can grow with your business. Will it accommodate higher volumes or more product types in the future?

● Adaptability: Look for machinery that can easily adapt to changes in production needs. This includes the ability to handle different formulations or adjust for new regulatory requirements.

● Technological Advancements: As technology evolves, ensure that your equipment can be upgraded or integrated with newer systems, such as automation and AI, to improve efficiency and reduce costs.

Future-proofing your investment ensures that your business remains competitive and prepared for market changes.

Choosing the right pharmaceutical equipment manufacturer is crucial for ensuring quality and efficiency. The top 10 manufacturers highlighted in this article are known for their innovation and reliability. Each brings unique strengths to the table, from advanced automation to global presence. Looking ahead, technological advancements like automation and AI will continue to drive the future of pharmaceutical equipment, making it even more efficient and adaptable.

Xingle has years of experience in production and sales of Pharmaceutical Equipment. If you want to know more about Pharmaceutical Equipment, feel free to contact us anytime with your inquiries.

A: Pharmaceutical equipment ensures precise dosage, consistency, and efficiency in drug manufacturing. It handles various stages, including mixing, filling, coating, and packaging, while maintaining compliance with regulatory standards like GMP.

A: Batch production involves making smaller quantities at different stages, while continuous production runs non-stop, providing higher efficiency and consistency in large-scale manufacturing.

A: Automation improves precision, reduces human error, increases efficiency, and ensures consistent production, which is crucial for meeting regulatory standards.

A: Pharmaceutical equipment must meet strict standards set by regulatory bodies like the FDA and WHO to ensure drugs are safe, effective, and of high quality, preventing costly recalls and ensuring patient safety.

7 Questions To Answer Before Buying A Capsule Filling Machine

How To Perform A Dosing Disc Thickness Calculation For Capsule Fillers

Dosator Vs. Dosing Disc: Comparing Two Capsule Filling Machines

Critical Capsule Filling Machine Parts Ensuring Production Efficiency

Liquid Hard Capsule Filling Technology Explained: Benefits, Process & Machines

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong