| Availability: | |

|---|---|

| Quantity: | |

XL-PWH

XINGLE

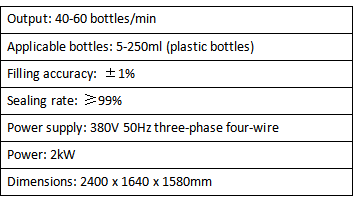

Rotary automatic spray bottle filling and sealing machine is a high-performance, fully automatic filling and sealing integrated equipment, specially designed for plastic and glass spray bottles ranging from 5 ml to 250 ml.

Spray Bottle Filling Machine uses advanced rotating disc positioning technology to ensure that the bottle body can be accurately positioned at each station, and cooperates with the electromagnetic oscillation or pneumatic system to automatically transport and fasten the nozzle, and finally complete the firm sealing operation.

The Vial filling machine has a compact design and stable operation. It can work independently and can be easily connected seamlessly with the front and rear equipment on your production line (such as bottle unscramblers, labeling machines, and cartoning machines) to achieve full automation of the production process. The optional dust cover can better meet the needs of higher-level clean production environments.

1. High-precision filling, zero waste of materials

1) The Spray Filling Machine adopts a high-precision metering pump or peristaltic pump filling system, and the filling accuracy is stably controlled within ±1%.

2) The extremely high precision ensures that the filling volume of each bottle of product is consistent, effectively avoiding excessive or insufficient input of materials, and saving a lot of production costs for the enterprise.

2. High-efficiency production and stable production capacity

1) The design speed is high and the stable production speed can reach 40-60 bottles/minute, which can significantly increase the production capacity of your production line.

2) Rotary continuous working mode, compared with intermittent equipment, has higher efficiency and smoother operation, and is very suitable for medium and large batch continuous production.

3. High sealing success rate and reliable quality

1) The sealing success rate of the Rotary filling and sealing machine is ≥99%, ensuring the sealing and safety of the product and effectively preventing leakage or contamination of the contents.

2) This is crucial to ensure the efficacy of drugs, the quality and user experience of daily chemical products, and greatly reduces after-sales risks.

4. Wide range of application, one machine for multiple purposes

1) Through simple mold replacement and parameter adjustment, it can quickly adapt to plastic or glass bottles of different specifications and materials between 5ml and 250ml.

2) This flexibility enables the Liquid Spray Filling Machine to cope with the production needs of multiple varieties and small batches, with a high return on investment.

5. High degree of automation and easy operation

1) From unpacking, filling, nozzle installation to sealing, the entire process is automated, greatly reducing reliance on manual labor and operating labor intensity.

2) Friendly human-machine interface, simple parameter setting, and easy for employees to quickly get started and maintain.

6. Stable and reliable power and structure

1) Using 380V industrial standard power supply, the power is strong and stable.

2) The power of the whole machine is only 2Kw, the energy consumption is low, and it conforms to the energy saving and environmental protection concept of modern industry.

Vial filling and sealing machine is an ideal choice in the field of spray product production and is widely used in the following industries:

1. Medicines: nasal sprays (such as rhinitis sprays), oral sprays, external skin sprays, disinfectant sprays, etc.

Requirements: Extremely high requirements for sterility, sealing, and filling accuracy. This equipment can perfectly comply with GMP related standards.

2. Personal care: perfume, moisturizing spray, hair styling spray, antiperspirant lotion, shaving foam, etc.

3. Household cleaning: glass cleaner, air freshener, furniture care spray, disinfectant, etc.

Demand: Pursue beautiful appearance, firm sealing, and efficient production. This equipment can effectively improve product image and production efficiency.

4. It is also suitable for filling and sealing of some industrial sprays, pet care sprays and other products.

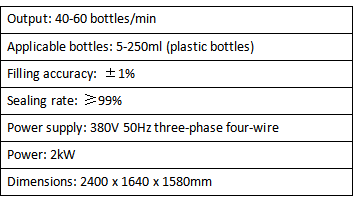

Rotary automatic spray bottle filling and sealing machine is a high-performance, fully automatic filling and sealing integrated equipment, specially designed for plastic and glass spray bottles ranging from 5 ml to 250 ml.

Spray Bottle Filling Machine uses advanced rotating disc positioning technology to ensure that the bottle body can be accurately positioned at each station, and cooperates with the electromagnetic oscillation or pneumatic system to automatically transport and fasten the nozzle, and finally complete the firm sealing operation.

The Vial filling machine has a compact design and stable operation. It can work independently and can be easily connected seamlessly with the front and rear equipment on your production line (such as bottle unscramblers, labeling machines, and cartoning machines) to achieve full automation of the production process. The optional dust cover can better meet the needs of higher-level clean production environments.

1. High-precision filling, zero waste of materials

1) The Spray Filling Machine adopts a high-precision metering pump or peristaltic pump filling system, and the filling accuracy is stably controlled within ±1%.

2) The extremely high precision ensures that the filling volume of each bottle of product is consistent, effectively avoiding excessive or insufficient input of materials, and saving a lot of production costs for the enterprise.

2. High-efficiency production and stable production capacity

1) The design speed is high and the stable production speed can reach 40-60 bottles/minute, which can significantly increase the production capacity of your production line.

2) Rotary continuous working mode, compared with intermittent equipment, has higher efficiency and smoother operation, and is very suitable for medium and large batch continuous production.

3. High sealing success rate and reliable quality

1) The sealing success rate of the Rotary filling and sealing machine is ≥99%, ensuring the sealing and safety of the product and effectively preventing leakage or contamination of the contents.

2) This is crucial to ensure the efficacy of drugs, the quality and user experience of daily chemical products, and greatly reduces after-sales risks.

4. Wide range of application, one machine for multiple purposes

1) Through simple mold replacement and parameter adjustment, it can quickly adapt to plastic or glass bottles of different specifications and materials between 5ml and 250ml.

2) This flexibility enables the Liquid Spray Filling Machine to cope with the production needs of multiple varieties and small batches, with a high return on investment.

5. High degree of automation and easy operation

1) From unpacking, filling, nozzle installation to sealing, the entire process is automated, greatly reducing reliance on manual labor and operating labor intensity.

2) Friendly human-machine interface, simple parameter setting, and easy for employees to quickly get started and maintain.

6. Stable and reliable power and structure

1) Using 380V industrial standard power supply, the power is strong and stable.

2) The power of the whole machine is only 2Kw, the energy consumption is low, and it conforms to the energy saving and environmental protection concept of modern industry.

Vial filling and sealing machine is an ideal choice in the field of spray product production and is widely used in the following industries:

1. Medicines: nasal sprays (such as rhinitis sprays), oral sprays, external skin sprays, disinfectant sprays, etc.

Requirements: Extremely high requirements for sterility, sealing, and filling accuracy. This equipment can perfectly comply with GMP related standards.

2. Personal care: perfume, moisturizing spray, hair styling spray, antiperspirant lotion, shaving foam, etc.

3. Household cleaning: glass cleaner, air freshener, furniture care spray, disinfectant, etc.

Demand: Pursue beautiful appearance, firm sealing, and efficient production. This equipment can effectively improve product image and production efficiency.

4. It is also suitable for filling and sealing of some industrial sprays, pet care sprays and other products.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong