| Availability: | |

|---|---|

| Quantity: | |

XL-QGS-Z

XINGLE

Vial filling machine adopts an integrated design concept, achieving fully automated operation from bottle feeding to finished product output, completely eliminating the pain points of low efficiency, high error rate, and high labor costs associated with traditional manual operation.

The equipment offers flexible capacity configuration options to meet the production needs of enterprises of different sizes.

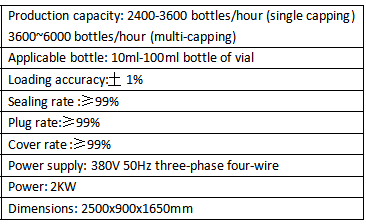

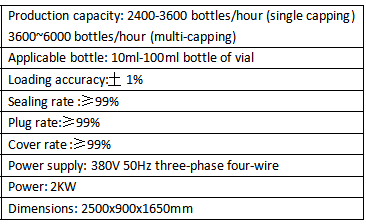

1. High-speed and stable operation: In single-head capping mode, the capacity can reach 2400-3600 bottles/hour; with the optional multi-head capping system, the capacity will soar to 3600-6000 bottles/hour, easily meeting your medium to large-volume production needs and helping enterprises expand production efficiently.

2. Accuracy up to ±1%: Utilizing a 4-6 head high-precision filling system, it ensures a highly consistent filling volume for each bottle, greatly reducing material waste and guaranteeing product quality uniformity and compliance.

3. Vial filling capping machine sealing rate ≥99%: Three-blade centrifugal capping technology ensures uniform pressure and a tight seal, guaranteeing product safety and shelf life.

4. Linear filling capping machine stopper loading rate ≥99%: A stable and reliable pneumatic stopper loading mechanism ensures that the stoppers are undamaged, uncontaminated, and accurately positioned.

5. Vial filling and capping machine capping rate ≥99%: An intelligent automatic capping system operates smoothly, greatly reducing manual intervention and failure rates.

6. Straight-line bottle inlet design: Simple structure, smooth operation, reduces bottle jamming and wear, and offers good compatibility with various bottle types.

7. High-quality components: Key components are sourced from well-known domestic and international brands, ensuring the durability and stability of the equipment during long-term continuous operation.

8. User-friendly design: The user interface is simple and intuitive, making it easy to replace standard parts and simplifying cleaning and maintenance, significantly reducing the learning and time costs for operators.

Choosing our Automatic Liquid Linear Filling Machine means you're getting more than just a piece of equipment; you're getting:

1. A productivity multiplier: freeing up manpower and enabling a leap in production capacity.

2. A guardian of product quality: precise filling and perfect sealing protect your products.

3. A cost saver: high precision reduces waste, and high stability lowers maintenance costs.

4. A solid backing for brand reputation: stable equipment produces high-quality products, enhancing market competitiveness.

Vial filling machine adopts an integrated design concept, achieving fully automated operation from bottle feeding to finished product output, completely eliminating the pain points of low efficiency, high error rate, and high labor costs associated with traditional manual operation.

The equipment offers flexible capacity configuration options to meet the production needs of enterprises of different sizes.

1. High-speed and stable operation: In single-head capping mode, the capacity can reach 2400-3600 bottles/hour; with the optional multi-head capping system, the capacity will soar to 3600-6000 bottles/hour, easily meeting your medium to large-volume production needs and helping enterprises expand production efficiently.

2. Accuracy up to ±1%: Utilizing a 4-6 head high-precision filling system, it ensures a highly consistent filling volume for each bottle, greatly reducing material waste and guaranteeing product quality uniformity and compliance.

3. Vial filling capping machine sealing rate ≥99%: Three-blade centrifugal capping technology ensures uniform pressure and a tight seal, guaranteeing product safety and shelf life.

4. Linear filling capping machine stopper loading rate ≥99%: A stable and reliable pneumatic stopper loading mechanism ensures that the stoppers are undamaged, uncontaminated, and accurately positioned.

5. Vial filling and capping machine capping rate ≥99%: An intelligent automatic capping system operates smoothly, greatly reducing manual intervention and failure rates.

6. Straight-line bottle inlet design: Simple structure, smooth operation, reduces bottle jamming and wear, and offers good compatibility with various bottle types.

7. High-quality components: Key components are sourced from well-known domestic and international brands, ensuring the durability and stability of the equipment during long-term continuous operation.

8. User-friendly design: The user interface is simple and intuitive, making it easy to replace standard parts and simplifying cleaning and maintenance, significantly reducing the learning and time costs for operators.

Choosing our Automatic Liquid Linear Filling Machine means you're getting more than just a piece of equipment; you're getting:

1. A productivity multiplier: freeing up manpower and enabling a leap in production capacity.

2. A guardian of product quality: precise filling and perfect sealing protect your products.

3. A cost saver: high precision reduces waste, and high stability lowers maintenance costs.

4. A solid backing for brand reputation: stable equipment produces high-quality products, enhancing market competitiveness.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong