| Availability: | |

|---|---|

| Quantity: | |

XL-QGS-1

XINGLE

This linear, high-speed vial filling and capping machine is a high-performance automated device that integrates filling, stoppering, capping, and capping functions. Designed specifically for handling vials ranging from 1ml to 50ml, it is widely used in pharmaceuticals, biological products, vaccines, diagnostic reagents, and other fields requiring extremely high filling accuracy and sealing performance.

Process Flow:

Bottle infeed → Positioning → Four-head simultaneous filling → Cylinder stoppering → Automatic capping → Three-blade centrifugal capping → Finished product output

The entire process is seamless and seamless, minimizing manual intervention and bottle wear.

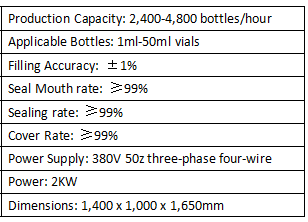

1. Efficient and Stable Production: Vial Filling Machine utilizes a linear layout with multi-station collaborative operation, achieving a production capacity of 2,400 to 4,800 bottles per hour, significantly improving production efficiency and meeting the needs of medium- and large-volume continuous production.

2. Wide Range of Applications: The machine offers excellent bottle compatibility and can easily accommodate a variety of vial sizes from 1ml to 50ml. Adjustment when changing vials is simple, providing high flexibility.

3. High-Precision Filling: Vial Filling and Capping Machine utilizes a multi-head linkage filling system, ensuring fill accuracy within ±1%, ensuring consistent and compliant product dosage.

4. High Capping Success Rate: Vial Filling and Sealing Machine integrates automatic capping and three-blade centrifugal capping technology, achieving capping, capping, and sealing rates of ≥99%, ensuring the tightness and integrity of the packaging.

5. Stable and Reliable Operation: The machine's core motion is driven by precision cylinders and mechanical structures, resulting in smooth operation and a low failure rate, ensuring the continuity and stability of the production line.

6. Humanized operation: Liquid vial filling machine supports two bottle feeding methods: bottle tray or hopper, adapting to different production environments. The structure is compact and the operation and maintenance are simple and intuitive.

Automatic filling and capping machines are widely used in industries requiring high-precision, high-sealing packaging, including but not limited to:

Pharmaceuticals: vaccines, parenteral solutions, lyophilized powder injections, oral solutions, etc.

Biotechnology: cell culture media, enzyme preparations, buffers, etc.

Diagnostic reagents: various chemiluminescent, immunoassay, and molecular diagnostic reagents.

Fine chemicals: high-value cosmetic essences and fragrance samples, etc.

This linear, high-speed vial filling and capping machine is a high-performance automated device that integrates filling, stoppering, capping, and capping functions. Designed specifically for handling vials ranging from 1ml to 50ml, it is widely used in pharmaceuticals, biological products, vaccines, diagnostic reagents, and other fields requiring extremely high filling accuracy and sealing performance.

Process Flow:

Bottle infeed → Positioning → Four-head simultaneous filling → Cylinder stoppering → Automatic capping → Three-blade centrifugal capping → Finished product output

The entire process is seamless and seamless, minimizing manual intervention and bottle wear.

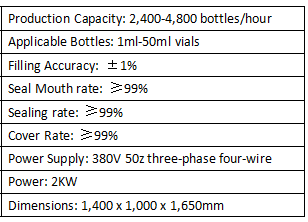

1. Efficient and Stable Production: Vial Filling Machine utilizes a linear layout with multi-station collaborative operation, achieving a production capacity of 2,400 to 4,800 bottles per hour, significantly improving production efficiency and meeting the needs of medium- and large-volume continuous production.

2. Wide Range of Applications: The machine offers excellent bottle compatibility and can easily accommodate a variety of vial sizes from 1ml to 50ml. Adjustment when changing vials is simple, providing high flexibility.

3. High-Precision Filling: Vial Filling and Capping Machine utilizes a multi-head linkage filling system, ensuring fill accuracy within ±1%, ensuring consistent and compliant product dosage.

4. High Capping Success Rate: Vial Filling and Sealing Machine integrates automatic capping and three-blade centrifugal capping technology, achieving capping, capping, and sealing rates of ≥99%, ensuring the tightness and integrity of the packaging.

5. Stable and Reliable Operation: The machine's core motion is driven by precision cylinders and mechanical structures, resulting in smooth operation and a low failure rate, ensuring the continuity and stability of the production line.

6. Humanized operation: Liquid vial filling machine supports two bottle feeding methods: bottle tray or hopper, adapting to different production environments. The structure is compact and the operation and maintenance are simple and intuitive.

Automatic filling and capping machines are widely used in industries requiring high-precision, high-sealing packaging, including but not limited to:

Pharmaceuticals: vaccines, parenteral solutions, lyophilized powder injections, oral solutions, etc.

Biotechnology: cell culture media, enzyme preparations, buffers, etc.

Diagnostic reagents: various chemiluminescent, immunoassay, and molecular diagnostic reagents.

Fine chemicals: high-value cosmetic essences and fragrance samples, etc.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong