| Availability: | |

|---|---|

| Quantity: | |

XL-QGS-2

XINGLE

This disc-type high-speed liquid vial filling and capping machine integrates advantages such as high efficiency, flexibility, precision, stability, and energy saving. It helps enterprises improve production efficiency, ensure product quality, and reduce production costs, making it an excellent equipment choice for enterprises to achieve automated and large-scale production.

1. High-efficiency production capacity, adaptable to large-scale needs

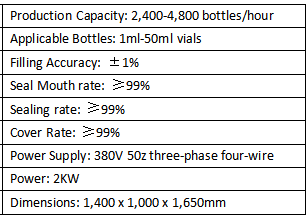

1) Vial Filling and Capping Machine can complete 2400~4800 bottles filling and capping operations per hour, significantly shortening the processing cycle of a single bottle and improving overall capacity utilization.

2) Adopting a disc-type operating structure, through precise workstation allocation and collaborative operation, it reduces the unit product production cost while ensuring quality.

2. Wide adaptability, flexibly responding to multiple specification requirements

1) Vial Filling Machine supports 1ml~50ml vials, covering common sizes for small-dose liquid packaging.

2) No need for extensive mold changes; bottle type switching can be achieved with simple adjustments, reducing changeover time and adapting to "multi-variety small-batch" or "multi-variety large-batch" production modes.

3. High-precision operation, ensuring stable product quality

1) Filling accuracy reaches... ±1%, employing high-precision flow control technology and drive system to ensure accurate and consistent dosage for each vial, meeting the high-precision requirements of pharmaceuticals and biological agents.

2) Sealing rate, stopper rate, and capping rate are all ≥99%: The capping process utilizes a gripping and screwing mechanism to ensure a tight seal, significantly reducing the scrap rate.

4. Stable and energy-saving, reducing production and operating costs

1) Adopting a 380V 50Hz three-phase four-wire power supply, meeting industrial standard power supply requirements, avoiding malfunctions caused by unstable power supply, and ensuring production continuity.

2) Liquid Vial Filling Machine has a power consumption of only 2KW, controlling energy consumption while maintaining high-efficiency production, conforming to the concept of energy conservation and environmental protection, and reducing the company's energy expenditure.

1. Adapts to small-dose liquids such as injectables, vaccines, and biological agents packaged in vials, meeting the stringent requirements of the pharmaceutical industry for dosage accuracy, sealing, and sterility.

2. Can be used for automated filling and capping of bottled pharmaceutical solutions such as antibiotics and vitamins, improving production efficiency and product qualification rate.

3. Automatic liquid filling machine is suitable for filling and capping small-volume liquid cosmetics such as serums, ampoules, and samples, ensuring uniform product dosage, sealed packaging, and preventing ingredient oxidation or contamination.

4. Vial Filling and Sealing Machine supports switching between multiple bottle types to meet the production needs of cosmetic brands.

5. Can be used for the production of small-bottle liquids such as oral liquids, health drinks, and condiments (such as small-dose essential oils and sauces), ensuring accurate filling, sealed packaging, and extending product shelf life.

6. High-efficiency production capacity adapts to the large-scale production needs of the food industry, reducing labor costs and production losses.

7. Suitable for filling and capping small-dose reagents, testing solutions, and special coatings, meeting the accuracy and sealing requirements of scientific research experiments and small-batch industrial reagent production.

This disc-type high-speed liquid vial filling and capping machine integrates advantages such as high efficiency, flexibility, precision, stability, and energy saving. It helps enterprises improve production efficiency, ensure product quality, and reduce production costs, making it an excellent equipment choice for enterprises to achieve automated and large-scale production.

1. High-efficiency production capacity, adaptable to large-scale needs

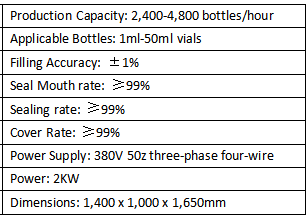

1) Vial Filling and Capping Machine can complete 2400~4800 bottles filling and capping operations per hour, significantly shortening the processing cycle of a single bottle and improving overall capacity utilization.

2) Adopting a disc-type operating structure, through precise workstation allocation and collaborative operation, it reduces the unit product production cost while ensuring quality.

2. Wide adaptability, flexibly responding to multiple specification requirements

1) Vial Filling Machine supports 1ml~50ml vials, covering common sizes for small-dose liquid packaging.

2) No need for extensive mold changes; bottle type switching can be achieved with simple adjustments, reducing changeover time and adapting to "multi-variety small-batch" or "multi-variety large-batch" production modes.

3. High-precision operation, ensuring stable product quality

1) Filling accuracy reaches... ±1%, employing high-precision flow control technology and drive system to ensure accurate and consistent dosage for each vial, meeting the high-precision requirements of pharmaceuticals and biological agents.

2) Sealing rate, stopper rate, and capping rate are all ≥99%: The capping process utilizes a gripping and screwing mechanism to ensure a tight seal, significantly reducing the scrap rate.

4. Stable and energy-saving, reducing production and operating costs

1) Adopting a 380V 50Hz three-phase four-wire power supply, meeting industrial standard power supply requirements, avoiding malfunctions caused by unstable power supply, and ensuring production continuity.

2) Liquid Vial Filling Machine has a power consumption of only 2KW, controlling energy consumption while maintaining high-efficiency production, conforming to the concept of energy conservation and environmental protection, and reducing the company's energy expenditure.

1. Adapts to small-dose liquids such as injectables, vaccines, and biological agents packaged in vials, meeting the stringent requirements of the pharmaceutical industry for dosage accuracy, sealing, and sterility.

2. Can be used for automated filling and capping of bottled pharmaceutical solutions such as antibiotics and vitamins, improving production efficiency and product qualification rate.

3. Automatic liquid filling machine is suitable for filling and capping small-volume liquid cosmetics such as serums, ampoules, and samples, ensuring uniform product dosage, sealed packaging, and preventing ingredient oxidation or contamination.

4. Vial Filling and Sealing Machine supports switching between multiple bottle types to meet the production needs of cosmetic brands.

5. Can be used for the production of small-bottle liquids such as oral liquids, health drinks, and condiments (such as small-dose essential oils and sauces), ensuring accurate filling, sealed packaging, and extending product shelf life.

6. High-efficiency production capacity adapts to the large-scale production needs of the food industry, reducing labor costs and production losses.

7. Suitable for filling and capping small-dose reagents, testing solutions, and special coatings, meeting the accuracy and sealing requirements of scientific research experiments and small-batch industrial reagent production.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong