| Availability: | |

|---|---|

| Quantity: | |

XL-KGF12(16)

XINGLE

The fully automatic filling and sealing machine for medicinal liquid vials is the core filling equipment in oral liquid preparation production lines. Designed specifically for the pharmaceutical industry, it provides integrated automation from liquid filling to capping. Its advanced design and compact structure effectively save production space and significantly improve production efficiency, making it an ideal choice for modern pharmaceutical companies to achieve efficient, precise, and compliant production.

(1) Fully Automated Operation, Exceptional Production Efficiency

The equipment integrates the three major processes of filling, capping, and sealing, providing automated, continuous operations that reduce manual intervention, minimize errors and contamination risks, and improve production speed, meeting the efficiency requirements of large-scale industrial production.

(2) Precise Bottle Feeding and Filling, Ensuring Product Quality

Stable Bottle Feeding System: The Vial Filling and Capping Machine uses a mesh belt to feed bottles, ensuring a stable trajectory and precise positioning, preventing bottles from tipping over or getting stuck, and ensuring smooth process transitions.

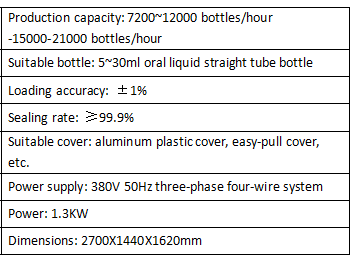

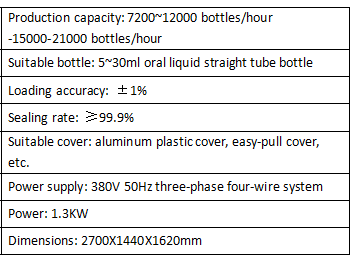

Low-Foam Precision Filling: The Vial Filling Machine is equipped with a twelve-head (or sixteen-head) local tracking filling system. The filling heads move synchronously with the bottles, controlling flow rate, reducing foam, ensuring accurate filling volume, and minimizing material waste.

(3) Efficient Capping and Stable Sealing, Improving Product Qualification Rate

Electromagnetic Oscillating Cap Feeding: High-frequency oscillation ensures orderly arrangement and precise feeding of caps, enabling fast capping and accurate positioning, achieving an industry-leading capping rate and preventing missed or misplaced caps.

Planetary Capping and Sealing: Equipped with a ten-head (or twelve-head) planetary capping device, the capping system provides uniform, multi-directional capping, stable and easily adjustable pressure, and a strong seal with a pass rate of ≥ 99.9%, ensuring safe storage and transportation of liquid medicines.

Liquid Vial Filling and Sealing Machine is widely applicable to the large-scale production of various medicinal liquids in the pharmaceutical industry, including oral liquids, syrups, and mixtures. It is particularly suitable for packaging 5-30ml straight-tube bottles and perfectly matches the production line configurations of different pharmaceutical companies. Whether it is medium-volume production for small and medium-sized pharmaceutical companies or high-speed, large-scale production for large pharmaceutical companies, the machine can be configured with a variety of filling and capping heads to meet diverse production needs, providing strong equipment support for companies to achieve capacity expansion and quality control.

The fully automatic filling and sealing machine for medicinal liquid vials is the core filling equipment in oral liquid preparation production lines. Designed specifically for the pharmaceutical industry, it provides integrated automation from liquid filling to capping. Its advanced design and compact structure effectively save production space and significantly improve production efficiency, making it an ideal choice for modern pharmaceutical companies to achieve efficient, precise, and compliant production.

(1) Fully Automated Operation, Exceptional Production Efficiency

The equipment integrates the three major processes of filling, capping, and sealing, providing automated, continuous operations that reduce manual intervention, minimize errors and contamination risks, and improve production speed, meeting the efficiency requirements of large-scale industrial production.

(2) Precise Bottle Feeding and Filling, Ensuring Product Quality

Stable Bottle Feeding System: The Vial Filling and Capping Machine uses a mesh belt to feed bottles, ensuring a stable trajectory and precise positioning, preventing bottles from tipping over or getting stuck, and ensuring smooth process transitions.

Low-Foam Precision Filling: The Vial Filling Machine is equipped with a twelve-head (or sixteen-head) local tracking filling system. The filling heads move synchronously with the bottles, controlling flow rate, reducing foam, ensuring accurate filling volume, and minimizing material waste.

(3) Efficient Capping and Stable Sealing, Improving Product Qualification Rate

Electromagnetic Oscillating Cap Feeding: High-frequency oscillation ensures orderly arrangement and precise feeding of caps, enabling fast capping and accurate positioning, achieving an industry-leading capping rate and preventing missed or misplaced caps.

Planetary Capping and Sealing: Equipped with a ten-head (or twelve-head) planetary capping device, the capping system provides uniform, multi-directional capping, stable and easily adjustable pressure, and a strong seal with a pass rate of ≥ 99.9%, ensuring safe storage and transportation of liquid medicines.

Liquid Vial Filling and Sealing Machine is widely applicable to the large-scale production of various medicinal liquids in the pharmaceutical industry, including oral liquids, syrups, and mixtures. It is particularly suitable for packaging 5-30ml straight-tube bottles and perfectly matches the production line configurations of different pharmaceutical companies. Whether it is medium-volume production for small and medium-sized pharmaceutical companies or high-speed, large-scale production for large pharmaceutical companies, the machine can be configured with a variety of filling and capping heads to meet diverse production needs, providing strong equipment support for companies to achieve capacity expansion and quality control.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong