| Availability: | |

|---|---|

| Quantity: | |

XL-QGS-Z

XINGLE

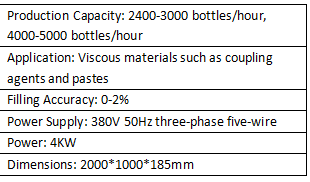

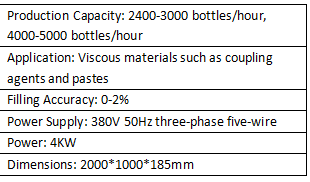

This fully automatic paste coupling agent filling and sealing machine is a modern filling equipment that integrates high efficiency, precision and stability. It is specially designed to handle the filling challenges of viscous pastes, medical coupling agents, and special materials containing fine particles. The equipment is highly integrated and has a high degree of automation. It can complete a complete set of processes such as bottle loading, quantitative filling, inner stopper loading, outer cap loading, capping and capping (sealing) in one go, significantly improving production efficiency and reducing labor costs and contamination risks.

1. Professional filling system to overcome the problem of sticky materials

1) Adopts a special pneumatic valve filling structure, specially designed for paste and coupling agent.

2) The Paste Filling And Sealing Machine is equipped with a precision adjustment device to achieve high-precision filling.

3) Ensure smooth and drip-free filling of high-viscosity, easy-to-draw, and granular materials.

4) Effectively solve common industry problems such as blocking and wall hanging in production.

2. Fully automatic integration, efficient and hygienic

1) Paste Filling And Sealing Machine has a compact design and integrates the entire process of bottle loading, filling, capping, capping/sealing, etc.

2) All processes are seamlessly connected to achieve full automation from empty bottles to finished products.

3) Significantly reduce manual intervention, ensure product hygiene, and improve production efficiency and standardization levels.

3. Highly adaptable design, easy to change production

1) Automatic Filling Machine can quickly adapt to different specifications of bottle and cap types by changing molds and adjusting parameters.

2) The production change operation is simple and convenient, and can fully meet the flexible production needs of multiple varieties and small batches.

4. Stable and reliable, excellent precision

1) The core components are from well-known brands, and the mechanical structure is sturdy and durable to ensure long-term stable operation of the equipment.

2) The filling accuracy is strictly controlled within ±2%, ensuring the consistency of product filling and reducing material waste.

Industrial filling and sealing machine is widely used in:

1. Medical device industry: filling and sealing of medical ultrasonic coupling agent.

2. Pharmaceutical industry: production of various external ointments, creams, and gels.

3. Cosmetics industry: filling of creams, facial masks, conditioners and other cream products.

4. Chemical industry: packaging of other chemical products with high viscosity and special properties.

This fully automatic paste coupling agent filling and sealing machine is a modern filling equipment that integrates high efficiency, precision and stability. It is specially designed to handle the filling challenges of viscous pastes, medical coupling agents, and special materials containing fine particles. The equipment is highly integrated and has a high degree of automation. It can complete a complete set of processes such as bottle loading, quantitative filling, inner stopper loading, outer cap loading, capping and capping (sealing) in one go, significantly improving production efficiency and reducing labor costs and contamination risks.

1. Professional filling system to overcome the problem of sticky materials

1) Adopts a special pneumatic valve filling structure, specially designed for paste and coupling agent.

2) The Paste Filling And Sealing Machine is equipped with a precision adjustment device to achieve high-precision filling.

3) Ensure smooth and drip-free filling of high-viscosity, easy-to-draw, and granular materials.

4) Effectively solve common industry problems such as blocking and wall hanging in production.

2. Fully automatic integration, efficient and hygienic

1) Paste Filling And Sealing Machine has a compact design and integrates the entire process of bottle loading, filling, capping, capping/sealing, etc.

2) All processes are seamlessly connected to achieve full automation from empty bottles to finished products.

3) Significantly reduce manual intervention, ensure product hygiene, and improve production efficiency and standardization levels.

3. Highly adaptable design, easy to change production

1) Automatic Filling Machine can quickly adapt to different specifications of bottle and cap types by changing molds and adjusting parameters.

2) The production change operation is simple and convenient, and can fully meet the flexible production needs of multiple varieties and small batches.

4. Stable and reliable, excellent precision

1) The core components are from well-known brands, and the mechanical structure is sturdy and durable to ensure long-term stable operation of the equipment.

2) The filling accuracy is strictly controlled within ±2%, ensuring the consistency of product filling and reducing material waste.

Industrial filling and sealing machine is widely used in:

1. Medical device industry: filling and sealing of medical ultrasonic coupling agent.

2. Pharmaceutical industry: production of various external ointments, creams, and gels.

3. Cosmetics industry: filling of creams, facial masks, conditioners and other cream products.

4. Chemical industry: packaging of other chemical products with high viscosity and special properties.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong