| Availability: | |

|---|---|

| Quantity: | |

XL-KGF-B

XINGLE

Tracking Filling Machine is a key filling machine for liquid production lines, precisely targeting the filling needs of glass and plastic bottles ranging from 50-500ml. Whether it's fluid drinking water and juice, slightly viscous sauces and daily detergents, or pharmaceutical liquids requiring stringent filling precision, it can stably adapt to meet diverse production scenarios across multiple categories and specifications, laying the foundation for flexible production line layouts.

1. Multiple Filling Heads + High Production Capacity

1) Automatic filling and sealing machine supports 6-16 adjustable filling heads, allowing businesses to choose according to their needs.

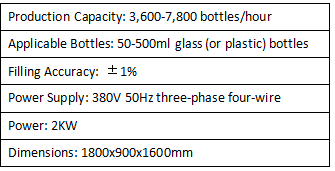

2) Equipped with a servo tracking system, it boasts a production capacity of 3,600-7,800 bottles per hour, suitable for large, medium, and small-scale production, enabling rapid order response.

2. Linear Bottle Feed Design

1) Automatic Filling Machine utilizes a scientific linear bottle feed structure, eliminating the problems of jamming and skew found in traditional equipment and reducing the failure rate.

2) It ensures precise alignment between the bottle and the filling station, reducing material waste and increasing effective production time.

3. Precision Filling + Low Foam

1) Vial Filling Machine utilizes servo tracking technology, achieving a filling accuracy of ±1%, exceeding industry standards.

2) The anti-foam filling nozzle and intelligent speed control reduce foam, achieving a product qualification rate exceeding 99.5%.

4. Advanced Compact Design

The Servo Filling and Sealing Machine utilizes a combination of advanced design and compact structure. While maintaining comprehensive functionality, it occupies a smaller footprint and is adaptable to production workshops of varying sizes.

With its wide adaptability and stable performance, the Industrial Filling and Sealing Machine can be deeply integrated into the liquid production processes of various industries:

1. Suitable for filling small and medium-sized bottled products such as juice, beverages, soy sauce, vinegar, and cooking oil;

2. Suitable for the production of products requiring extremely high filling precision, such as oral liquids, disinfectants, and medical lotions;

3. Suitable for filling small and medium-sized bottles of daily chemical liquids such as shampoo, shower gel, hand soap, and laundry detergent;

4. Suitable for meeting the precision filling needs of some small and medium-sized chemical reagents, lubricants, and other liquids.

The Automatic Small Bottle Servo Tracking Filling and Sealing Machine, with its core advantages of high efficiency, precision, and stability, helps companies overcome capacity bottlenecks and quality challenges in the filling process. It is a powerful tool for promoting automation upgrades and improving market competitiveness for liquid production companies.

Tracking Filling Machine is a key filling machine for liquid production lines, precisely targeting the filling needs of glass and plastic bottles ranging from 50-500ml. Whether it's fluid drinking water and juice, slightly viscous sauces and daily detergents, or pharmaceutical liquids requiring stringent filling precision, it can stably adapt to meet diverse production scenarios across multiple categories and specifications, laying the foundation for flexible production line layouts.

1. Multiple Filling Heads + High Production Capacity

1) Automatic filling and sealing machine supports 6-16 adjustable filling heads, allowing businesses to choose according to their needs.

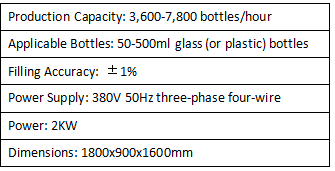

2) Equipped with a servo tracking system, it boasts a production capacity of 3,600-7,800 bottles per hour, suitable for large, medium, and small-scale production, enabling rapid order response.

2. Linear Bottle Feed Design

1) Automatic Filling Machine utilizes a scientific linear bottle feed structure, eliminating the problems of jamming and skew found in traditional equipment and reducing the failure rate.

2) It ensures precise alignment between the bottle and the filling station, reducing material waste and increasing effective production time.

3. Precision Filling + Low Foam

1) Vial Filling Machine utilizes servo tracking technology, achieving a filling accuracy of ±1%, exceeding industry standards.

2) The anti-foam filling nozzle and intelligent speed control reduce foam, achieving a product qualification rate exceeding 99.5%.

4. Advanced Compact Design

The Servo Filling and Sealing Machine utilizes a combination of advanced design and compact structure. While maintaining comprehensive functionality, it occupies a smaller footprint and is adaptable to production workshops of varying sizes.

With its wide adaptability and stable performance, the Industrial Filling and Sealing Machine can be deeply integrated into the liquid production processes of various industries:

1. Suitable for filling small and medium-sized bottled products such as juice, beverages, soy sauce, vinegar, and cooking oil;

2. Suitable for the production of products requiring extremely high filling precision, such as oral liquids, disinfectants, and medical lotions;

3. Suitable for filling small and medium-sized bottles of daily chemical liquids such as shampoo, shower gel, hand soap, and laundry detergent;

4. Suitable for meeting the precision filling needs of some small and medium-sized chemical reagents, lubricants, and other liquids.

The Automatic Small Bottle Servo Tracking Filling and Sealing Machine, with its core advantages of high efficiency, precision, and stability, helps companies overcome capacity bottlenecks and quality challenges in the filling process. It is a powerful tool for promoting automation upgrades and improving market competitiveness for liquid production companies.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong