Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

Capsule filling machines play a crucial role in the pharmaceutical and supplement industries. They ensure accuracy and speed in production. Whether for personal or business use, these machines improve cost-effectiveness and efficiency. In this article, we'll explore the top 9 capsule filling machines, their features, and benefits.

Choosing the right capsule filling machine depends on several factors. Here are the main considerations to keep in mind.

● Manual Machines: Ideal for small-scale production or home use. These require more effort but are low-cost options.

● Semi-Automatic Machines: These machines require some manual input but automate most of the process. They are suitable for medium-scale operations.

● Automatic Machines: Best for large-scale operations. They require minimal human intervention and can fill a large volume quickly and accurately.

● Material Construction: Machines made from stailess steel are more durable and easier to clean compared to those made from acrylic or other materials.

● Speed and Efficiency: The rate of filling varies. Some machines can fill up to 250,000 capsules per hour, while others are slower but offer better control for smaller batches.

● Capsule Size Compatibility: Ensure the machine can handle the capsule sizes you need (e.g., #000, #00, #0, etc.). Some machines are versatile and can accommodate multiple sizes.

● Accuracy and Consistency: Look for machines with a high level of accuracy in filling, ensuring consistent dosages in each capsule.

● Ease of Cleaning and Maintenance: Machines with easy-to-disassemble parts and smooth surfaces help maintain hygiene, which is crucial for both pharmaceuticals and supplements.

When selecting a machine, match the production volume with your needs. If you're just starting or producing small batches, a manual or semi-automatic machine is more than enough. For larger, ongoing production, you'll need an automatic machine that can handle high volumes and reduce labor costs.

It's crucial that the machine complies with Good Manufacturing Practices (GMP) to ensure product quality and safety. GMP compliance guarantees that your machine adheres to necessary safety standards, reducing the risk of contamination and production errors.

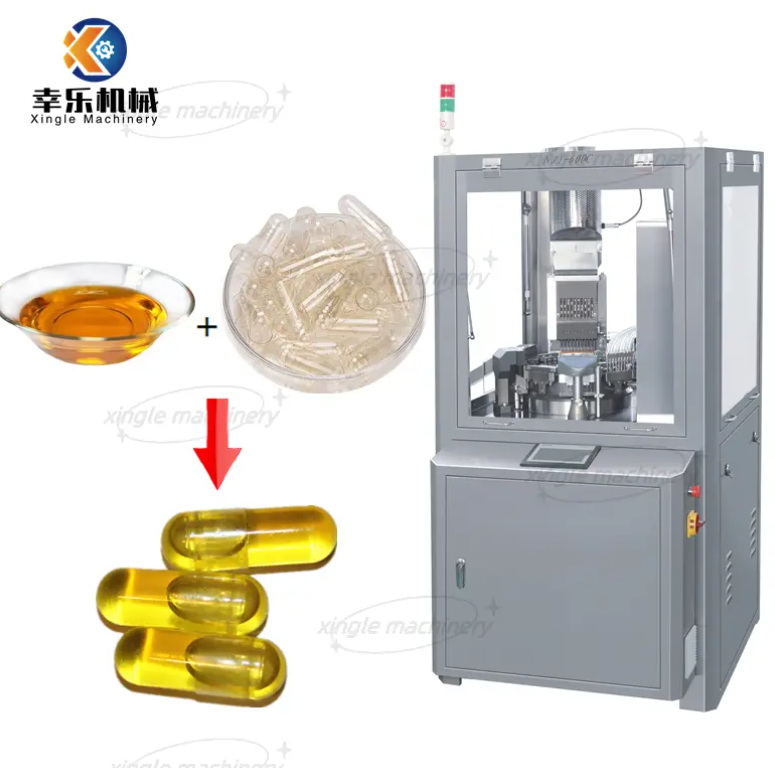

This fully automatic soft capsule filling machine is designed to handle liquid and semi-liquid products. It ensures smooth, efficient filling by incorporating a built-in chiller. The chiller helps maintain optimal temperatures throughout the process, which is crucial for temperature-sensitive materials. Perfect for industries requiring high precision and high-speed production, it is ideal for filling soft gelatin capsules.

● Stepless Timing Control: Allows precise filling adjustments to meet specific production needs.

● Built-in Chiller: Maintains consistent temperatures, ensuring product quality, especially for sensitive formulations.

● High-Speed Operation: Designed for large-scale production with high precision.

● Easy Operation: The user-friendly interface makes it simple to set up and manage the machine, even for operators with minimal experience.

● Low Maintenance: Its design ensures that maintenance is quick and straightforward, reducing downtime and increasing productivity.

This machine is perfect for manufacturers who produce soft gelatin capsules containing liquid fillings. It's commonly used in industries such as pharmaceuticals, dietary supplements, and even fish oils. If you're working with delicate or temperature-sensitive ingredients, such as oils or extracts, this machine will help maintain consistency throughout the filling process.

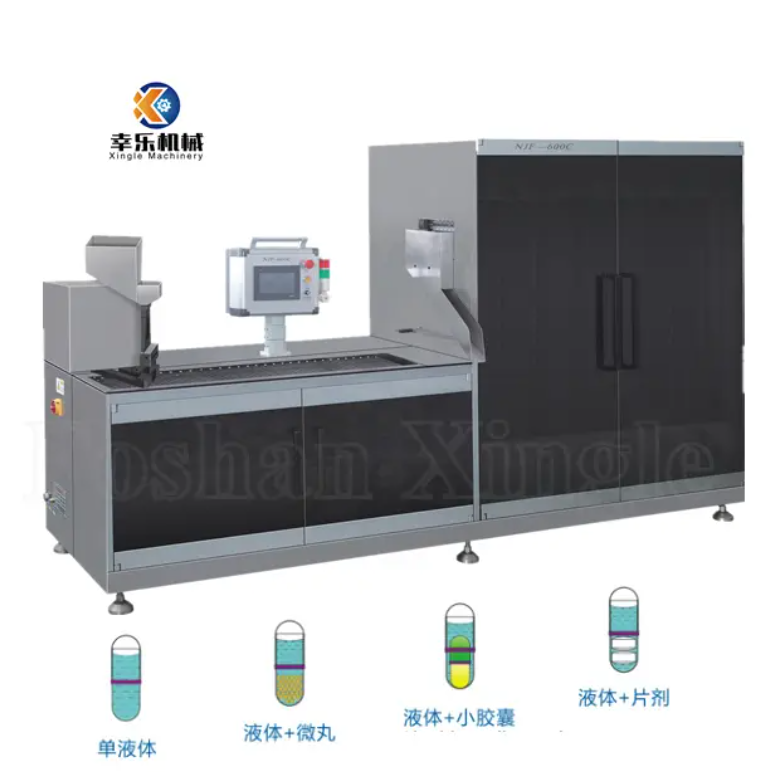

This fully automatic machine is designed specifically for filling liquid capsules with high precision. Constructed from stainless steel, it offers excellent durability and adheres to strict hygiene standards. It's an ideal choice for the medical and pharmaceutical industries where reliability and precision are critical.

● Liquid and Semi-Liquid Compatibility: Perfect for a variety of liquid and semi-liquid formulations, including oils, syrups, and extracts.

● High-Speed, Automatic System: Provides fast filling cycles while maintaining accuracy and consistency across large production volumes.

● Stainless Steel Construction: Durable and resistant to corrosion, ensuring compliance with hygiene and GMP (Good Manufacturing Practice) standards.

● Easy to Clean and Maintain: Designed for effortless cleaning, minimizing downtime between batches and ensuring continuous production.

● Precise Dosing: The machine ensures each capsule receives the exact required dose, making it reliable for pharmaceutical applications.

Pharmaceutical manufacturers requiring high-quality liquid capsule production for medical and therapeutic applications. Whether you're producing supplements, essential oils, or pharmaceutical liquids, this machine delivers high efficiency and performance.

The Semi-Automatic Capsule Filling Machine is designed to fill granules and powders into capsules. It offers a simple, user-friendly operation, making it ideal for small to medium production runs. This machine is particularly beneficial for businesses in need of a cost-effective, reliable solution for capsule filling.

● Semi-Automatic Operation: Manual loading of capsules while the machine automates the filling process. Simple and effective.

● Powder and Granule Compatibility: Works well with both powder and granule fillings, offering flexibility for different production needs.

● Compact Design: Small footprint that fits into most workspaces without compromising on capacity or efficiency.

● Easy Operation: With a user-friendly interface, this machine is easy to set up and operate, even for new users.

● Low Maintenance: Requires minimal maintenance, ensuring smooth operation over extended periods.

This machine is perfect for small businesses, research labs, or pharmaceutical companies looking for a dependable semi-automatic capsule filling solution. Whether you're filling capsules with powders, granules, or other similar materials, it provides an efficient and affordable option.

The Xingle Vertical Powder Automatic Capsule Filling Machine is specifically designed for efficient and high-speed powder filling into capsules. Its vertical design ensures smooth material flow and minimal waste, making it an ideal choice for pharmaceutical manufacturing environments. With automatic settings, it allows for precise control over the powder filling process, making it suitable for large-scale production.

● Automatic Powder Filling: Fully automatic, the machine offers precise powder filling with adjustable settings for various powder formulations.

● Vertical Design: The vertical structure optimizes material flow, reducing the chance of blockages and ensuring a smooth, continuous filling process.

● High Productivity: Capable of handling high-volume production with minimal downtime, it meets the demands of large-scale pharmaceutical manufacturing.

● GMP Compliant: Complies with Good Manufacturing Practices (GMP), ensuring the highest industry standards in production.

● Ease of Use: Designed for easy operation, it simplifies setup, reducing the time and effort required for production runs.

This machine is best suited for pharmaceutical companies that require efficient, high-speed powder capsule filling. It is perfect for companies producing pharmaceutical-grade powders in bulk, ensuring both accuracy and high productivity.

This Filling Machine is a versatile, high-speed solution for filling both hard gelatin and liquid capsules. This multi-functional machine is ideal for large-scale production, offering pharmaceutical manufacturers the flexibility to produce a variety of capsule types efficiently. Its advanced design ensures smooth operation and precise filling for both capsule types.

● Dual Function: This machine can fill both hard gelatin capsules and liquid capsules, making it highly versatile.

● Advanced PLC Control System: Equipped with a programmable logic controller (PLC), it ensures precise operations and enhanced automation, reducing the risk of errors.

● High-Speed Operation: Designed for large-scale production, it can fill large volumes quickly without compromising on accuracy.

● GMP Compliant: Fully compliant with Good Manufacturing Practices (GMP), ensuring the highest standards of hygiene and safety in pharmaceutical production.

● User-Friendly Interface: The easy-to-use interface simplifies machine operation, making it ideal for businesses looking to minimize training time for operators.

This machine is perfect for pharmaceutical manufacturers needing a flexible and efficient capsule filling solution. Whether you're producing hard gelatin capsules, liquid capsules, or both, this machine provides an efficient, reliable option for large-scale production.

The Xingle NJP-1200 Automatic Capsule Filling Machine is an efficient, compact solution for small to medium-scale capsule filling production. It offers high-speed performance in a user-friendly design, ideal for businesses looking to optimize their production without taking up much space. The machine is simple to operate, making it accessible even to operators with limited experience.

● High Production Capacity: Can fill up to 120,000 capsules per hour, making it ideal for moderate-scale operations.

● Minimal Operator Involvement: The high-speed operation reduces the need for constant supervision, allowing operators to focus on other tasks.

● Easy to Clean and Maintain: Designed for quick cleaning and minimal maintenance, reducing downtime between production runs.

● Compact Design: Small footprint makes it perfect for businesses with limited space but still requires high-efficiency production.

This machine is perfect for businesses with moderate production needs, offering a reliable and compact solution for capsule filling. Whether you are a growing pharmaceutical company or a supplement manufacturer, the Xingle NJP-1200 offers the flexibility and performance to meet your production goals.

The Rotary Continuous Vitamin A Liquid Capsule Filling Machine is specifically designed for the continuous filling of liquid capsules. This machine is especially effective for filling oil-based products like vitamin A, ensuring precision and speed in high-demand environments. It offers automated operation, reducing the need for manual intervention while enhancing efficiency in continuous production processes.

● Continuous Rotary Operation: This design enables higher efficiency and allows for continuous production, making it ideal for high-volume production runs.

● Suitable for Oil-Based Products: Designed to handle liquid formulations, it excels at filling oil-based liquids, such as vitamin A, essential oils, and other nutraceuticals.

● GMP Compliant: The machine meets Good Manufacturing Practices (GMP) standards, ensuring it is suitable for pharmaceutical and nutraceutical applications that require strict quality and hygiene controls.

● Automated Operation: Reduces labor costs and ensures precise filling without the need for constant supervision.

This machine is perfect for manufacturers producing liquid capsules, especially those focused on the continuous, high-demand production of vitamin-based supplements. Its efficiency and precision make it a great choice for businesses looking to scale production while maintaining quality.

The Low Noise Capsule Filling Machine is specifically designed to operate quietly while filling capsules. Ideal for environments where noise reduction is a priority, it uses intermittent motion to ensure efficient filling. This machine provides high-speed filling, making it perfect for large-scale operations that need both efficiency and a quieter working atmosphere.

● Low Noise Operation: Designed for quieter operation, it's perfect for environments where noise levels must be minimized.

● Intermittent Motion Design: Enhances efficiency by ensuring smooth and consistent motion during filling, reducing the risk of errors.

● High-Speed Filling System: Capable of handling large volumes of capsule filling while maintaining high accuracy and speed.

● User-Friendly Interface: Makes operation simple, even for new users, reducing the learning curve.

This machine is ideal for pharmaceutical companies and nutraceutical manufacturers that need a high-speed, efficient filling process without compromising a quiet working environment. It's especially suited for environments where noise control is critical but where large-scale production is still needed.

This Filling Machine is specifically designed for filling hard gelatin capsules with liquid formulations like fish oil and other viscous liquids. Its multihead design enhances the efficiency of the filling process, ensuring higher throughput and better precision. The machine uses intermittent motion, optimizing its speed and effectiveness while maintaining product quality.

● Multihead Filling System: Allows for high-speed operation, significantly increasing production efficiency and ensuring precise filling.

● Suitable for Viscous Liquids: Designed to handle thick liquids like fish oil, it can accommodate a wide range of viscous formulations.

● GMP Compliant: Fully compliant with Good Manufacturing Practices (GMP), ensuring it meets the stringent standards required in pharmaceutical and nutraceutical applications.

● Intermittent Motion Design: The filling process is smooth and efficient, reducing cycle time and improving overall productivity.

This machine is ideal for manufacturers producing liquid-filled hard gelatin capsules, particularly for fish oil and similar products. It is perfect for businesses looking for a reliable, high-speed filling machine capable of handling viscous formulations.

Before choosing a capsule filling machine, determine your required production capacity. Is your business in the early stages or scaling up? Machines vary in speed and output. Larger-scale operations need machines capable of handling high volumes, while smaller businesses may opt for machines that fit their current needs.

Different capsule sizes are used depending on the product. Ensure the machine you're considering can accommodate the specific capsule sizes you need, such as #0, #00, or #1. Some machines offer flexible configurations, allowing you to switch between sizes quickly, while others are more specialized.

Choose a machine designed to handle your specific filling materials. Whether you're working with powders, granules, liquids, or oils, make sure the machine can efficiently process the intended material. Some machines are versatile and can handle multiple material types, while others may be optimized for specific formulations like fish oil or powders.

Capsule filling machines come in manual, semi-automatic, and automatic models. Manual machines are more affordable but require more operator intervention. Semi-automatic machines provide a good balance of automation and cost. Automatic machines, while higher in price, offer the highest level of efficiency and require the least human involvement, making them suitable for larger-scale operations.

Ensure the machine complies with relevant industry standards and certifications, especially if you're in the pharmaceutical or nutraceutical industries. Look for machines that meet GMP (Good Manufacturing Practices) standards to ensure product safety and consistency. Certifications help ensure your production process remains compliant and meets regulatory requirements.

In this guide, we've reviewed the top 9 capsule filling machines, focusing on their features, efficiency, and suitability for various needs. Whether you need a machine for small or large-scale production, it's essential to consider your specific requirements, such as capsule size, filling material, and automation level. Choose a machine that best fits your production scale and budget to ensure optimal performance and reliability in your operations.

A: Yes, many capsule filling machines offer interchangeable parts, allowing you to fill different capsule sizes, such as #0, #00, or #1.

A: Yes, most machines are designed for easy cleaning. Automatic and semi-automatic machines often come with removable parts to facilitate quick cleaning and maintenance.

A: Manual machines require full operator involvement, while semi-automatic machines reduce labor with some automated functions. Automatic machines handle the entire process, requiring minimal human intervention, and are best for high-volume production.

7 Questions To Answer Before Buying A Capsule Filling Machine

How To Perform A Dosing Disc Thickness Calculation For Capsule Fillers

Dosator Vs. Dosing Disc: Comparing Two Capsule Filling Machines

Critical Capsule Filling Machine Parts Ensuring Production Efficiency

Liquid Hard Capsule Filling Technology Explained: Benefits, Process & Machines

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong