| Availability: | |

|---|---|

| Quantity: | |

XL-FZK-120

XINGLE

Industrial rapid granulator efficiently converts irregular, bulky or large granular materials into uniformly sized, standard-compliant fine granules through crushing, cutting, and extrusion. With its exceptional stability, flexible applicability, and convenient operation, it has become an indispensable key piece of equipment in production processes in the pharmaceutical, food, and chemical industries.

Working Principle of the Granule Rapid Granulator:

Material enters the granulation chamber vertically from a top feed hopper. Inside, high-speed rotating granulation knives rapidly cut and crush the material. Centrifugal force then forces the material through a screen with a preset aperture. The size of the mesh directly determines the final granule size. The uniformly extruded granules then pass through a discharge hopper and are collected in a container, completing the granulation process.

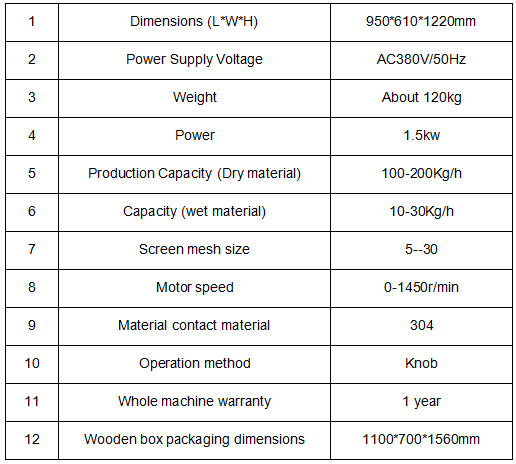

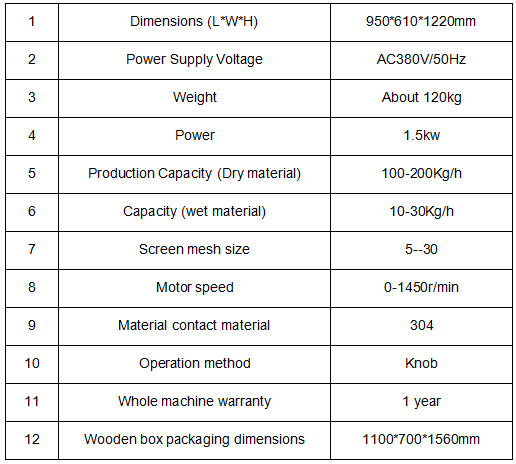

1. Dual-Function Granulator: Uniquely combines dry and wet granulation, with a dry material capacity of 100-200 kg/h and a wet material capacity of 10-30 kg/h. Mode switching is quick and efficient, ensuring high utilization.

2. Controllable Particle Size: The granulator is equipped with a 5-30 mesh interchangeable screen for easy adjustment, ensuring uniform granulation and consistent quality.

3. Clean and Safe: All contact parts of the granulating equipment are made of 304 stainless steel, meeting GMP and other hygiene standards, ensuring corrosion resistance and easy cleaning.

4. Smooth and Efficient: The FOMA wheel design allows for easy movement, stable high-speed operation, and low noise, resulting in fast granulation and excellent efficiency.

5. Easy Operation: The knob-operated stepless speed adjustment (0-1450 rpm) and modular design allow for easy disassembly and cleaning, saving time and maintenance.

Pharmaceutical Industry

1. Used for efficient granulation of bulk materials obtained after wet granulation, dry granulation, or swing granulation, producing uniform granules for subsequent tableting, capsule filling, or packaging.

Food Industry

1. Used for granulating sugars and condiments (such as MSG and chicken essence) to improve their flowability and solubility and prevent clumping.

2. Used for producing solid beverages (such as milk tea powder, coffee granules, and soy milk powder) to form uniform granules, improving product dissolution and appearance.

3. Used for preparing food additives (such as flavor granules and pigment granules) to ensure accurate dosage and uniform mixing.

Chemical Industry

1. Used for forming and granulating catalysts, molecular sieves, and other products to increase their specific surface area and reaction efficiency.

2. Used for granulating raw materials such as plastics and resins to facilitate injection molding or extrusion processing.

3. Used for granulating powders such as dyes, pigments, and fertilizers to reduce dust, improve physical properties, and facilitate transportation and use.

Industrial rapid granulator efficiently converts irregular, bulky or large granular materials into uniformly sized, standard-compliant fine granules through crushing, cutting, and extrusion. With its exceptional stability, flexible applicability, and convenient operation, it has become an indispensable key piece of equipment in production processes in the pharmaceutical, food, and chemical industries.

Working Principle of the Granule Rapid Granulator:

Material enters the granulation chamber vertically from a top feed hopper. Inside, high-speed rotating granulation knives rapidly cut and crush the material. Centrifugal force then forces the material through a screen with a preset aperture. The size of the mesh directly determines the final granule size. The uniformly extruded granules then pass through a discharge hopper and are collected in a container, completing the granulation process.

1. Dual-Function Granulator: Uniquely combines dry and wet granulation, with a dry material capacity of 100-200 kg/h and a wet material capacity of 10-30 kg/h. Mode switching is quick and efficient, ensuring high utilization.

2. Controllable Particle Size: The granulator is equipped with a 5-30 mesh interchangeable screen for easy adjustment, ensuring uniform granulation and consistent quality.

3. Clean and Safe: All contact parts of the granulating equipment are made of 304 stainless steel, meeting GMP and other hygiene standards, ensuring corrosion resistance and easy cleaning.

4. Smooth and Efficient: The FOMA wheel design allows for easy movement, stable high-speed operation, and low noise, resulting in fast granulation and excellent efficiency.

5. Easy Operation: The knob-operated stepless speed adjustment (0-1450 rpm) and modular design allow for easy disassembly and cleaning, saving time and maintenance.

Pharmaceutical Industry

1. Used for efficient granulation of bulk materials obtained after wet granulation, dry granulation, or swing granulation, producing uniform granules for subsequent tableting, capsule filling, or packaging.

Food Industry

1. Used for granulating sugars and condiments (such as MSG and chicken essence) to improve their flowability and solubility and prevent clumping.

2. Used for producing solid beverages (such as milk tea powder, coffee granules, and soy milk powder) to form uniform granules, improving product dissolution and appearance.

3. Used for preparing food additives (such as flavor granules and pigment granules) to ensure accurate dosage and uniform mixing.

Chemical Industry

1. Used for forming and granulating catalysts, molecular sieves, and other products to increase their specific surface area and reaction efficiency.

2. Used for granulating raw materials such as plastics and resins to facilitate injection molding or extrusion processing.

3. Used for granulating powders such as dyes, pigments, and fertilizers to reduce dust, improve physical properties, and facilitate transportation and use.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong