| Availability: | |

|---|---|

| Quantity: | |

XL-GHL-20

XINGLE

High Efficiency Granulator is intelligently controlled by a PLC program to complete the entire process of mixing, humidifying and granulating powder materials and adhesives in a closed container at one time. It is widely used in pharmaceutical, food, chemical and other industries, and is especially suitable for R&D experiments and small batch, multi-variety flexible production. This equipment is ideal for improving process consistency and ensuring product quality.

Wet Mixer Granulator integrates mixing, pulping and granulation processes into one. When working, the stirring paddle drives the powder to move three-dimensionally in the container to achieve rapid and even mixing. After adding the binder, the material forms a soft material, which is then broken into wet particles of the required size by a high-speed cutting knife.

The final properties of the particles can be precisely controlled through the rotation speed, time of stirring and cutting, and the amount of binder used. After the granulation is completed, the materials can be easily discharged and connected with downstream equipment (such as wet granulator, fluidized bed dryer, etc.) to form a continuous production line.

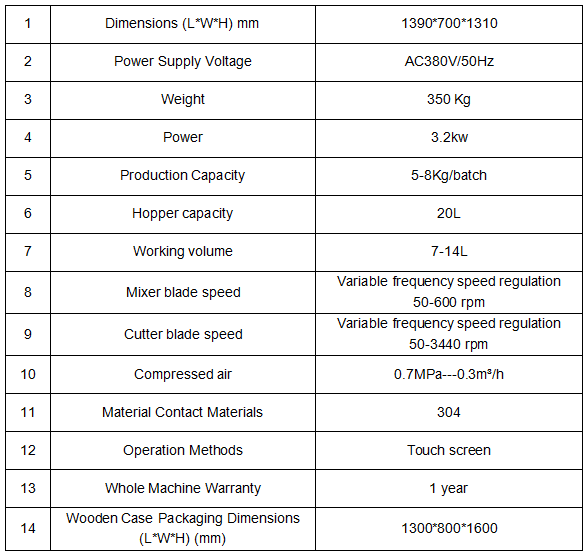

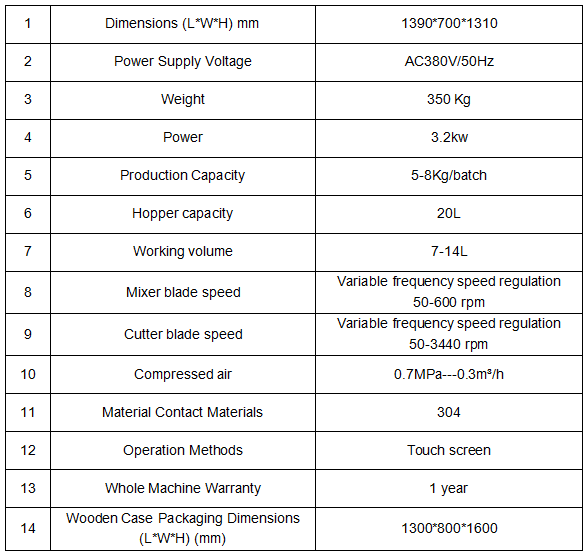

1. Intelligent control, stable and repeatable process: Wet Mixing GranulatorPLC + touch screen control, process parameters can be stored and recalled to ensure consistency between batches and comply with cGMP.

2. Three-dimensional high-efficiency mixing without stratification: The mixing paddle is speed-regulated through frequency conversion (50-600 rpm), and three-dimensional mixing ensures that the materials are evenly mixed, and there is no stratification even if the main and auxiliary materials are greatly different.

3. Powerful cutting and granulation, the particles are uniform and controllable: the high-speed cutting knife cooperates with the variable frequency speed adjustment (frequency variable speed adjustment 50-3440 rpm) to easily control the particle properties to ensure uniformity and controllability.

4. Modular design, flexible response to R&D and production: the granulating machine has a working volume of 7-14L and a production capacity of 5-8Kg per batch. The optional exchangeable hopper is an ideal platform for small-batch R&D and pilot testing.

5. Convenient connection: The discharge port of the Pharmaceutical Granulator can be connected to the granulator or vacuum conveyed to the fluidized bed to easily form a closed production line.

Stainless Steel Granulator is not only a piece of equipment, but also a complete wet granulation solution. Through the intelligent design integrating machinery, electricity and gas, it makes the complex granulation process simple, reliable and traceable, significantly improving R&D efficiency and production efficiency. It is a powerful help for modern laboratories and production workshops to achieve process excellence.

High Efficiency Granulator is intelligently controlled by a PLC program to complete the entire process of mixing, humidifying and granulating powder materials and adhesives in a closed container at one time. It is widely used in pharmaceutical, food, chemical and other industries, and is especially suitable for R&D experiments and small batch, multi-variety flexible production. This equipment is ideal for improving process consistency and ensuring product quality.

Wet Mixer Granulator integrates mixing, pulping and granulation processes into one. When working, the stirring paddle drives the powder to move three-dimensionally in the container to achieve rapid and even mixing. After adding the binder, the material forms a soft material, which is then broken into wet particles of the required size by a high-speed cutting knife.

The final properties of the particles can be precisely controlled through the rotation speed, time of stirring and cutting, and the amount of binder used. After the granulation is completed, the materials can be easily discharged and connected with downstream equipment (such as wet granulator, fluidized bed dryer, etc.) to form a continuous production line.

1. Intelligent control, stable and repeatable process: Wet Mixing GranulatorPLC + touch screen control, process parameters can be stored and recalled to ensure consistency between batches and comply with cGMP.

2. Three-dimensional high-efficiency mixing without stratification: The mixing paddle is speed-regulated through frequency conversion (50-600 rpm), and three-dimensional mixing ensures that the materials are evenly mixed, and there is no stratification even if the main and auxiliary materials are greatly different.

3. Powerful cutting and granulation, the particles are uniform and controllable: the high-speed cutting knife cooperates with the variable frequency speed adjustment (frequency variable speed adjustment 50-3440 rpm) to easily control the particle properties to ensure uniformity and controllability.

4. Modular design, flexible response to R&D and production: the granulating machine has a working volume of 7-14L and a production capacity of 5-8Kg per batch. The optional exchangeable hopper is an ideal platform for small-batch R&D and pilot testing.

5. Convenient connection: The discharge port of the Pharmaceutical Granulator can be connected to the granulator or vacuum conveyed to the fluidized bed to easily form a closed production line.

Stainless Steel Granulator is not only a piece of equipment, but also a complete wet granulation solution. Through the intelligent design integrating machinery, electricity and gas, it makes the complex granulation process simple, reliable and traceable, significantly improving R&D efficiency and production efficiency. It is a powerful help for modern laboratories and production workshops to achieve process excellence.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong