| Availability: | |

|---|---|

| Quantity: | |

XL-CJP

XINGLE

In the demanding world of pharmaceutical and health product manufacturing, the cleanliness of every glass bottle directly impacts product safety and quality. Driven by an unwavering commitment to efficiency, reliability, and compliance, we proudly present our auger-type ultrasonic bottle washer—your highly efficient cleanliness guardian on the production line, laying an impeccable foundation for your product quality.

1. Superior Cleaning Performance, Protecting Products from Zero Risk

1) Deep Cleaning: Utilizing advanced ultrasonic technology, billions of microbubbles are generated to cavitate and explode the bottle's interior and exterior, thoroughly removing stubborn stains and microparticles.

2) Multi-Media Fine Washing Process: After ultrasonic pre-washing, the bottles are precisely turned over in a auger and sequentially rinsed and dried with purified water → water for injection → purified compressed air multiple times. This rigorous cleaning process ensures no residue and no microbial contamination inside the bottle.

2. Highly Efficient and Flexible Production Capacity to Meet Diverse Needs

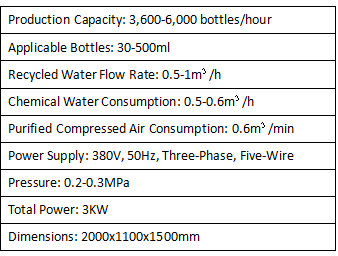

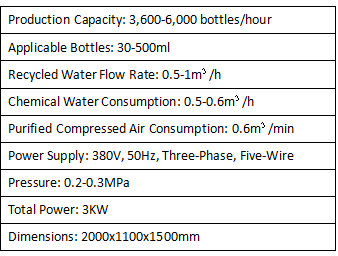

1) Excellent Output: The Ultrasonic Bottle Washing Machine boasts an astonishing efficiency of up to 6000 bottles/hour, significantly accelerating your production line.

2) Flexible Adaptability: The Industrial Bottle Washing Machine is perfectly compatible with various glass bottle sizes from 30ml to 500ml, making it the ideal choice for high-volume production of single-variety products. 3) Modular Design: The glass bottle washing machine can be flexibly configured with 1 to 5 augers operating simultaneously to meet your production needs, achieving precise matching of capacity and future expansion.

3. Ultimate Cleaning Guarantee, Exceeding Industry Standards

1) Circulating Water System: The automatic bottle washing machine is equipped with two filters to ensure the cleanliness of recycled water.

2) Injection Water System: A booster pump with a dedicated precision filter ensures the quality of high-purity injection water.

3) Air Supply System: Compressed air passes through a high-efficiency filter, providing a dry, oil-free, and dust-free purging air supply.

1. Cleaning of glass bottles for large-volume injections, small-volume injections, and oral liquids.

2. Cleaning of bottles for various high-end oral liquids and nutritional supplements.

3. Other industries with high requirements for the cleanliness of glass containers.

In the demanding world of pharmaceutical and health product manufacturing, the cleanliness of every glass bottle directly impacts product safety and quality. Driven by an unwavering commitment to efficiency, reliability, and compliance, we proudly present our auger-type ultrasonic bottle washer—your highly efficient cleanliness guardian on the production line, laying an impeccable foundation for your product quality.

1. Superior Cleaning Performance, Protecting Products from Zero Risk

1) Deep Cleaning: Utilizing advanced ultrasonic technology, billions of microbubbles are generated to cavitate and explode the bottle's interior and exterior, thoroughly removing stubborn stains and microparticles.

2) Multi-Media Fine Washing Process: After ultrasonic pre-washing, the bottles are precisely turned over in a auger and sequentially rinsed and dried with purified water → water for injection → purified compressed air multiple times. This rigorous cleaning process ensures no residue and no microbial contamination inside the bottle.

2. Highly Efficient and Flexible Production Capacity to Meet Diverse Needs

1) Excellent Output: The Ultrasonic Bottle Washing Machine boasts an astonishing efficiency of up to 6000 bottles/hour, significantly accelerating your production line.

2) Flexible Adaptability: The Industrial Bottle Washing Machine is perfectly compatible with various glass bottle sizes from 30ml to 500ml, making it the ideal choice for high-volume production of single-variety products. 3) Modular Design: The glass bottle washing machine can be flexibly configured with 1 to 5 augers operating simultaneously to meet your production needs, achieving precise matching of capacity and future expansion.

3. Ultimate Cleaning Guarantee, Exceeding Industry Standards

1) Circulating Water System: The automatic bottle washing machine is equipped with two filters to ensure the cleanliness of recycled water.

2) Injection Water System: A booster pump with a dedicated precision filter ensures the quality of high-purity injection water.

3) Air Supply System: Compressed air passes through a high-efficiency filter, providing a dry, oil-free, and dust-free purging air supply.

1. Cleaning of glass bottles for large-volume injections, small-volume injections, and oral liquids.

2. Cleaning of bottles for various high-end oral liquids and nutritional supplements.

3. Other industries with high requirements for the cleanliness of glass containers.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong