| Availability: | |

|---|---|

| Quantity: | |

XXPT-01

XINGLE

The small star-shaped positioning self-adhesive labeling machine is designed to achieve optimal production goals. The labeling process is fully automated, offering simple operation, fast production speeds, and uniform, aesthetically pleasing label placement. It is suitable for labeling round containers in the pharmaceutical, chemical, and food industries, and can apply full and semi-circular labels. Optional ribbon printers and inkjet printers can also be used to simultaneously print batch numbers, production dates, and other information. This integrated labeling and coding process reduces packaging steps and improves production efficiency.

Workflow

Manual placement of labeled products (on-line or bottle unscrambling turntable) -> Products are automatically separated, corrected and conveyed -> Product inspection -> Product labeling -> Collecting labeled products (entering the next process) -> Taking away products.

1. High-precision core drive system, stable and reliable performance

1) High-precision intermittent divider: Ensures stable operation at high speeds, and extremely precise indexing (i.e., bottle rotation and positioning) of the bottle labeling machine.

2) High transmission torque: The positioning labeling machine can handle larger and heavier bottles, extending its applicability.

3) Self-locking function: Automatically locks after indexing, completely eliminating minor post-positioning jitter and laying a solid foundation for high-precision labeling.

2. Precise and intelligent labeling positioning control system

1) The labeling wheel is driven by a motor: The label delivery length is precisely controlled by controlling the number of pulses, achieving digital precision control.

2) Accurate label position calculation: Ensures that each label is accurately applied to the designated location on the bottle, effectively avoiding issues such as overlapping or uneven label spacing.

3. Wide Range of Applications and Flexible Adjustment

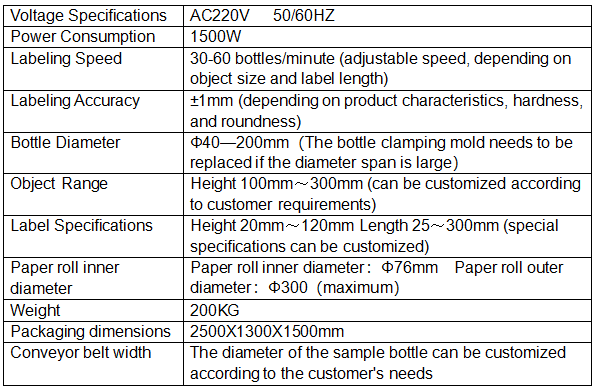

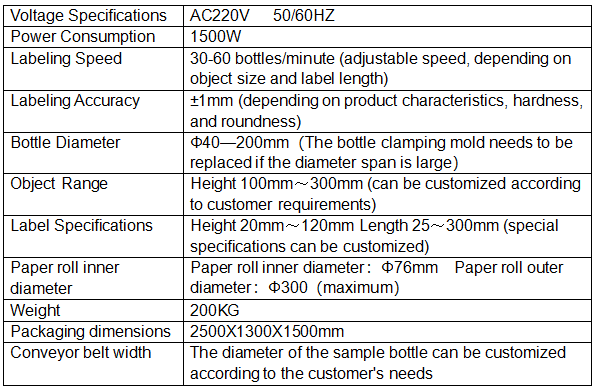

1) Adjustable Labeling Speed (30-60 bottles/minute): Users can flexibly adjust production efficiency based on specific production needs and product characteristics (such as bottle size and label length).

2) The sticker labeling machine can handle a wide range of bottle diameters (Ø40-200mm): It can accommodate a variety of bottle sizes, and can switch between different bottle shapes by simply replacing the bottle clamping mold.

4. Guaranteed Overall Labeling Accuracy

Overall labeling accuracy reaches ±1mm: Even with normal fluctuations in product characteristics, it maintains extremely high labeling accuracy, effectively improving product appearance quality and consistency.

1. Daily Chemical and Cosmetics Industry

Shampoo, shower gel, skincare, perfume, and cosmetic bottles, etc.

This industry features a variety of bottle shapes and high-end label materials (such as transparent film and laser labels). Furthermore, labeling requires bubble-free, wrinkle-free, and precise positioning. The high stability and precise stop motion of the star-shaped labeling machine perfectly meet these requirements.

2. Food and Beverage Industry

Condiment bottles (soy sauce, vinegar), beverage bottles, high-end mineral water, honey jars, etc.

High-speed, continuous production is required, and labels often wrap around the bottle. The star-shaped labeling machine's stable high-speed operation and high transmission torque ensure accurate wrap-around labeling at high speeds.

3. Pharmaceutical Industry

Cialis bottles, oral solution bottles, and medicine bottles, etc.

The pharmaceutical industry requires extremely high labeling accuracy and has strict requirements for equipment stability and traceability. The star-shaped labeling machine's self-locking positioning function ensures consistent stop motion, making it ideal for pharmaceutical labeling.

4. Lubricant and Chemical Industry

Motor oil drums, chemical raw material bottles, and lubricant bottles, etc. These products usually have large and heavy bottles, which require strong power. The large transmission torque of the star-shaped machine enables it to stably clamp and rotate large bottles to complete labeling.

The small star-shaped positioning self-adhesive labeling machine is designed to achieve optimal production goals. The labeling process is fully automated, offering simple operation, fast production speeds, and uniform, aesthetically pleasing label placement. It is suitable for labeling round containers in the pharmaceutical, chemical, and food industries, and can apply full and semi-circular labels. Optional ribbon printers and inkjet printers can also be used to simultaneously print batch numbers, production dates, and other information. This integrated labeling and coding process reduces packaging steps and improves production efficiency.

Workflow

Manual placement of labeled products (on-line or bottle unscrambling turntable) -> Products are automatically separated, corrected and conveyed -> Product inspection -> Product labeling -> Collecting labeled products (entering the next process) -> Taking away products.

1. High-precision core drive system, stable and reliable performance

1) High-precision intermittent divider: Ensures stable operation at high speeds, and extremely precise indexing (i.e., bottle rotation and positioning) of the bottle labeling machine.

2) High transmission torque: The positioning labeling machine can handle larger and heavier bottles, extending its applicability.

3) Self-locking function: Automatically locks after indexing, completely eliminating minor post-positioning jitter and laying a solid foundation for high-precision labeling.

2. Precise and intelligent labeling positioning control system

1) The labeling wheel is driven by a motor: The label delivery length is precisely controlled by controlling the number of pulses, achieving digital precision control.

2) Accurate label position calculation: Ensures that each label is accurately applied to the designated location on the bottle, effectively avoiding issues such as overlapping or uneven label spacing.

3. Wide Range of Applications and Flexible Adjustment

1) Adjustable Labeling Speed (30-60 bottles/minute): Users can flexibly adjust production efficiency based on specific production needs and product characteristics (such as bottle size and label length).

2) The sticker labeling machine can handle a wide range of bottle diameters (Ø40-200mm): It can accommodate a variety of bottle sizes, and can switch between different bottle shapes by simply replacing the bottle clamping mold.

4. Guaranteed Overall Labeling Accuracy

Overall labeling accuracy reaches ±1mm: Even with normal fluctuations in product characteristics, it maintains extremely high labeling accuracy, effectively improving product appearance quality and consistency.

1. Daily Chemical and Cosmetics Industry

Shampoo, shower gel, skincare, perfume, and cosmetic bottles, etc.

This industry features a variety of bottle shapes and high-end label materials (such as transparent film and laser labels). Furthermore, labeling requires bubble-free, wrinkle-free, and precise positioning. The high stability and precise stop motion of the star-shaped labeling machine perfectly meet these requirements.

2. Food and Beverage Industry

Condiment bottles (soy sauce, vinegar), beverage bottles, high-end mineral water, honey jars, etc.

High-speed, continuous production is required, and labels often wrap around the bottle. The star-shaped labeling machine's stable high-speed operation and high transmission torque ensure accurate wrap-around labeling at high speeds.

3. Pharmaceutical Industry

Cialis bottles, oral solution bottles, and medicine bottles, etc.

The pharmaceutical industry requires extremely high labeling accuracy and has strict requirements for equipment stability and traceability. The star-shaped labeling machine's self-locking positioning function ensures consistent stop motion, making it ideal for pharmaceutical labeling.

4. Lubricant and Chemical Industry

Motor oil drums, chemical raw material bottles, and lubricant bottles, etc. These products usually have large and heavy bottles, which require strong power. The large transmission torque of the star-shaped machine enables it to stably clamp and rotate large bottles to complete labeling.

Copyright © 2023 Foshan Xingle Machinery Equipment Co.,Ltd. 粤ICP备2023093194号 All rights reserved. Privacy Policy | Sitemap | Support By Leadong